We’re often given the opportunity to head out into the field and visit with one of our partner manufacturers, and because these companies are on the leading edge of racing and street performance research and development, it’s an opportunity we’d be foolish to turn down when it’s given. So when we were offered a personal tour of one of the leading torque converter manufacturers, ProTorque Converters, we jumped at the chance, made the plans, and took the ride to their Bohemia, New York facility.

ProTorque has been in the torque converter business since 1983 and started operating as a small, local torque converter rebuilder opened by company patriarch Joe Rivera, Sr. Transitioning into the performance industry was a natural arc, given Rivera Sr.’s affinity for street rod projects and ability to design his own products. While ‘Mr. Joe’ is still involved in the company’s operations, its current level of success within the racing world can be directly attributed to Joe Rivera, Jr., the company’s General Manager and Lead Developer.

With over 16,000 square feet of space dedicated to their torque converter business, ProTorque is a full-line manufacturing facility that produces tens of thousands of torque converters per year, from hard-to-find remanufactured import models up to the fully-custom Revolution Series converters that are found in many of today’s top runners.

Of course, we can’t show you the proprietary information that’s helped to make the company so successful, but we hope you’ll enjoy what information we were able to glean on our visit.

How It Works

The theory behind how a torque converter operates is simple, yet complex – it is a hydrodynamic fluid coupling that transfers power from the engine through to the automatic transmission and serves the same basic function as a clutch in a manual-transmission-equipped car.

If you want a simple lesson on the basics, check out this great video produced by none other than the US Army. Warning – it’s almost 13 minutes long, but if you’re willing to invest the time you’re sure to learn something new about torque converters. Then head over the jump for the rest of the article.

In The Shop

Upon entering the factory area of the ProTorque facility, Joe guided us to the beginning of the process, the “entry point”, if you will, where they take in the stock-style converters that are there to be rebuilt. Although their parts are winning in the racing world, the company hasn’t forgotten its roots and continues to be one of the largest OEM-style converter remanufacturers on the East Coast. Rivera, Jr. is very proud of the fact that the company strives to be green in their operations; everything from the shavings generated when converters are cut open to the used transmission oil is collected for recycling or is re-used in the process of what they do.

This massive storage area holds thousands of converter cores that have been sorted; many of them cut apart already for inspection and cataloging.

Building the actual torque converter is a process that has been broken down into stations within the ProTorque facility. “Raw Materials” for a torque converter manufacturer, at least for stock-style designs, consist of rebuildable stock, as it’s simply too expensive to build all-new torque converters for most applications, and there are very few parts that wear out.

Each of the workers is responsible for one step of the process, and that familiarity breeds consistency and accuracy. Disassembling and cleaning take place at one station, while the next station inspects the parts before the construction process begins. The parts are assembled according to each individual order to exacting tolerances, and then precision-welded, checked for leaks, and covered in the traditional ProTorque black finish before boxing and shipping.

The weld line for each converter is measured and tacked before being checked for runout again. Final welding is done robotically with this twin-head welder. The converter is then checked for leaks in this tank prior to being cleaned again and finish-painted prior to delivery. These steps apply to any of Pro Torque's converters.

Building Hardcore Racing Converters

A ProTorque Revolution Series torque converter, however, is far from an assembly-line torque converter. The turbine and pump designs are selected for each particular application from the reams of data that Rivera, Jr. keeps on hand, and the front covers and stators are machined from chunks of billet for strength and consistency.

Torque converters are different for every single application, and their specifications take into account vehicle weight, horsepower, torque, and gear ratio along with a host of other things that Rivera looks at during the consultation process. Stator fin angles can be different along with pump and turbine fin angles, and Rivera, Jr. stresses that it’s the complete package that has to be designed to work together.

Left to Right - One of ProTorque's Revolution Series billet front covers. These have been designed to retain strength where necessary while remaining as light as possible. The pump has been reinforced in all critical areas with an anti-balloon plate (or two). Rivera was very eager to show off the precision welding his equipment is capable of performing.

Joe also shared with us that he has an extensive amount of OE design and development experience, and the knowledge he gained while working with an unnamed carmarker translated well into the performance industry and gave him an idea.

Once he realized that he was on to something with his discovery, the decision came to invest the time and energy into making the design the best it could be, and to that end, Pro Torque has a dedicated CNC facility building all of the stators found in their Revolution Series torque converters.

Unfortunately, the actual construction process is proprietary, so we can’t show you any billets undergoing the knife in the cabinet. We can say that the machining process itself is a beautiful thing, and if you want the benefits of what it offers you’re going to have to buy one of Joe’s converters. Record-setting racers like Tim Lynch, Mike Murillo, John Kolivas, Danny Lowry, Kyle Heuttel, Troy Coughlin, and Jose Gonzalez are all running ProTorque torque converters, and that’s just a small glimpse of the racer base Rivera, Jr. has built up as part of his team.

This is the only glimpse we got into the CNC area. The repeatability these machines offer means that ProTorque can confidently deliver their products to perform.

Maximizing Design With Tuning Data

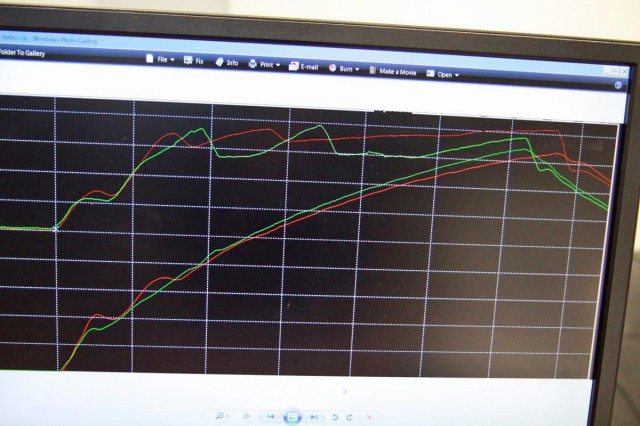

The image above is just a sample Racepak graph like those that Joe spends his life dissecting. His use of technology and understanding how to extrapolate the data he receives into a torque converter that performs as advertised is uncanny.

During our tour, we had a great conversation with Joe about what strategies he uses to produce these torque converters that have seemingly turned the racing world on its ear over the last couple of seasons. One would think he’d point to his own research and development efforts, but he was very quick to throw much of the credit towards the racing teams he’s been lucky enough to work with during the design and implementation phase of the product. “These guys told me they were looking for a converter that would be loose on the bottom to help multiply torque, and then tight on the top to run hard out the back, and that’s what we deliver,” Rivera, Jr. said.

Parts Development

The three basic parts of a torque converter are the pump, the turbine, and the stator, which is the single most important element in a performance torque converter, as it affects the oil flow returning from the turbine to the pump. Recognizing this fact, Pro Torque has devoted all of their attention over the last half-decade to stator development and how it affects performance in a power-adder application – a ton of testing, refinement, and more testing with some of the top racers and manufacturers in the business.

Although it seems like ProTorque has just come on the scene within the last few years, Rivera, Jr. explained that late-model tuning gurus like Hennessey, Mallet, and Calloway, as well as racing legends like Pat Musi and Kenny Duttweiler were using his parts years ago before it became fashionable.

Their development work centers around the use of technology to improve their product, and to that end Rivera, Jr. showed us some of the Racepak datalogs he was working on with a professional team the day we were there.

“The thing we’re trying to do for all of these power-adder cars is to have them work like they have a clutch – loose down low to get the motor as happy as it can be as soon as possible like a clutch, and couple as soon as possible and as hard as possible. The main thing is to look for a converter to have enough capacity of the given engine output. It allows whoever is tuning the car to manipulate the power in a way they’ve never been able to before,” he explained.

“It took me over 500 stator designs and a couple of times wanting to quit on the idea before we finally figured it out. We’ve been privileged to work with some top-notch race teams who believed in our product and were willing to test with us to design the Revolution Series converters,” he continued.

Left to Right - ProTorque keeps billet stators on hand for many different converter styles. Here are just three of the various designs Rivera and company have used over the years. Putting the converters together is a painstaking process that requires measuring and re-checking the work before closing the converter up - they have to be right the first time.

Don’t think that the Revolution Series converters’ development is where the focus will stop, though. Rivera, Jr. has designs on revamping how power is transmitted for some of the other small-tire, big-power classes like X275 and Ultimate Street – it’s just a matter of time until he has enough testing information from enough of the Team ProTorque members to make those new designs a reality. The race car development process has already trickled down into their CSD billet stator design for the late-model Camaro and Challenger street converters.

Spy pics - Joe showed off his newest front cover, still in development. The press-fit spline-drive hub modular design is still in the development phase, but he says these are coming soon. They will permit the use of a universal flexplate design, while the mounting pads are removable and will be available in varying thicknesses - no more shims!

We came away from our tour thoroughly impressed with the facility and the team of craftsmen working there, as each is dedicated to the plan of doing their part to put their racers into the winner’s circle. So far, the performance speaks volumes.