[1]

[1]

When it comes to business, there are many sayings that are thought provoking and are meant to motivate people to achieve. One of those sayings is, “A company is only as good as its employees,” and another is “A company’s employees are a reflection of its leaders.” Both sayings are only going to apply to a company that cares about its employees, and about employees who believe in what they’re doing. We visited one such company recently, and found that both sayings hold true.

Looking rather calm and quiet from the outside, there's a lot of metal being heated up, bent, stamped and powdercoated beyond these walls.

Nestled in the corner of a freeway offramp in Visalia, California, for the past few decades is Hellwig Products [4]. When you first see them along the freeway, it’s hard to get a true feel for what goes on inside the manufacturing facility, so we packed up our gear and headed North to see what goes on inside.

They opened their doors to show us what they do best, but there wasn’t one piece of machinery that could match the family tradition that Hellwig has generated since the mid-1940s. Their dedication, concern for quality, and genuine respect for the customer has ultimately created a passion that has spanned four generations.

Humble Beginnings

[5]

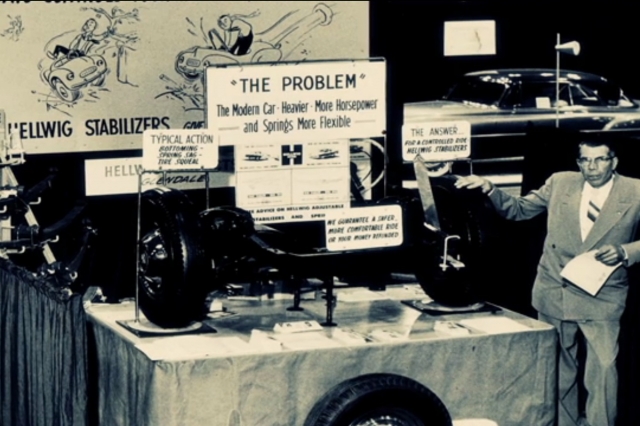

[5]Pitching Hellwig Products back in the day, with full-size displays just like they still do today.

Rudy Hellwig was a pioneer in the sway bar industry. In 1941, he got a patent for his overload springs, and in 1946 he started Hellwig Products, pounding out all of their stabilizer springs by hand. His son, Don, used to go out with him in the beginning on weekends, and they would look for someone with a Ford that had transverse leaf springs.

Often times, the car owner was in their driveway washing their car, and Rudy would approach them and offer to install the springs on their car for just $7 – installed. Don recalls spending many weekends on his back, under a car, installing Hellwig’s original products.

By the late ’60s and ’70s, Rudy was making sway bars and they were 100% American made, as they are today. While many people might know about Hellwig for their RV and camper sway control products, their sway bars for musclecars have been generating equal amounts of attention.

Hellwig has been in the same location since the 1960s, but they have continually grown to not only add new products, but to expand their own capabilities to perform everything they need in-house. When quality is one of the most important factors, you have to know that anything sent out is handled with the same attention to detail.

They used to send out their sway bars for powdercoating, but when quality began to come into question, they realized that it was their own name on the product, not the powdercoater, so they made the proverbial executive decision to start powdercoating their parts in house. David Wheeler, Product Specialist at Hellwig, said, “We wanted to start controlling the overall quality of our products, from start to finish. The only way we can feel confident is when we know that we don’t have to rely on someone else to have the same dedication that we have.”

The only way to really control quality is to do it yourself, and Hellwig even does their own powdercoating.

Wheeler has been with Hellwig for about ten years, but you would think he’s been with the company forever. He believes in what he does, and doesn’t rest until he knows that he’s given it his all. At trade shows, like SEMA, he’s out there in the trenches and instead of just telling you about a product and what it fits, he explains to you how they designed it, and why they designed it that particular way.

Then one of the ladies in the office told me that I would get bored if I didn’t continue working at Hellwig. -Melanie White

Hellwig Products – A Family Tradition

Greeting us in the front office was Melanie White, a fourth generation Hellwig and the current Vice President. Her great grandfather’s passion and dedication is evident when you talk to her about Hellwig Products. She has become very proud of what her family has created, and she knows that the only way she can be successful in this business is to carry on the family tradition that has been handed down from the generations preceding her.

She told us, “While I was going to school, I wasn’t sure what I was going to do. Then one of the ladies in the office told me that I would get bored if I didn’t continue working at Hellwig.” It was a keen observation, because Melanie has dedicated her career to Hellwig, following in the footsteps of her father, Mark Hellwig, President of Hellwig Products.

Some of the equipment has been around for decades, with modern updates as technology increases.

This has been a family run company for over 65 years, and it’s easy to tell that both Mark and Melanie love what they do and have that same passion for the business that Don and Rudy had. When you talk to either one of them about sway bars, or any of their other products, they genuinely know the business and the products, and love the competition they get from other companies. Mark said, “We like to have a little competition. It keeps us on our toes. It makes us try that much harder to be the best that we can.”

[12]

[12]With furnace temps reaching 2,300 degrees, you can imagine what the temperatures inside the shop must be on a hot summer day.

Taking the Red Hot Tour

Say what you will about women in the automotive industry, White refutes any assumed stereotypes. She gave us the tour of the facility, and it was very clear she’s not just the owner’s daughter. She knows what’s going on out back in the shop, and she’s well aware of who’s doing what, what needs to be done, and how the business is run as a day-to-day operation. She loves the passion that her family has for this business, and just couldn’t imagine doing anything else.

[13]

[13]Even the picture seems to be putting out some heat, imagine standing this close to it on a daily basis like Felipe Reyes does.

They run two shifts making sway bars and load control products, and watching everyone work together and get their piece of the puzzle completed takes a lot more effort and teamwork than you would think. While some of them work independently, there are others who rely on each other – like a well-oiled machine.

We watched a pair of workers who proved that timing is everything, because if they didn’t work in unison someone could seriously get injured – especially when working with red-hot sway bars for a big rig. The huge sway bars for big rigs are heavy, and there’s no room for mistakes; both had to work well together and also had to communicate incredibly well. Any shortage of teamwork, or assumption about whether the other was ready, and someone could be going to the hospital.

While blacksmithing has been a huge part of the business since it began, and is still the biggest part of what they do, Hellwig has not rested on their laurels and let technology get ahead of them. They make sure that they keep up with the trends and with improved methods to keep their production shop running smoothly and efficiently.

Top: Working as a team isn't a suggestion for Ramon Martinez and Miguel Lara, it's a requirement. Bottom: Andrew Rivera uses the injection heater, which takes only 30 seconds to get the end of the bar red hot like this.

One of the very cool gadgets that Wheeler showed us was their injection heater. For tooling the ends of the sway bars, what used to take several minutes to heat up the end of the bar and get it hot enough to work with now takes only 30 seconds. Imagine how much that increases production when you make thousands of sway bars and the worker doesn’t have to stand there holding a bar for a few minutes.

Trade Shows and Traveling

Mark Hellwig, can often be seen at trade shows, showing the automotive industry what’s new and unique at Hellwig. He’s not just someone who sits in the front office shuffling paperwork, Hellwig is fully aware of every aspect of the business as well. As a family owned and run business, we could tell that it wasn’t just handed down from generation to generation, each successor had to work, and work hard, in order to run the business.

Whether it's SEMA, PRI, or a Goodguys car show weekend, Hellwig is there with products that make your car or truck handle better than it ever has. Gary Wright (right) spends 40% of his time at shows like this.

He knows that taking care of the customer, and providing the best possible product is part of that family tradition. It’s often difficult to run a company and to be at all of the trade shows, it’s a lot of work and requires a lot of travel. Melanie and Mark are both out of the office quite a bit, but for many of the shows that they can’t attend, that’s where Gary Wright fills in. Gary has only been with Hellwig for about a year, but you would never know it. As the Western Regional Sales Manager, he spends about 40% of his time on the road, attending trade shows and car shows, and sharing suspension secrets of the trade.

Dependable Products, Dependable People

[21]

[21]Wheeler’s own Chevelle utilizes Hellwig suspension products, and will be seen a bit more for the next year or so at trade shows – sans the body.

One person that the Hellwigs truly rely on is David Wheeler. We’ve talked to Wheeler a few times over the years, and if there ever was anyone who has passion for what they do, Wheeler is the poster child. It’s not to say that you can’t find that passion in the entire company, but we have to say that Wheeler has proven time and time again that he truly is a master in his industry.

While some companies are simply satisfied with being able to install their components, Wheeler says they will often re-engineer something so that it will install easier, and perform even better. Wright explained this logic to us at Del Mar this past Spring when we talked about their sway bars for off-road vehicles. He told us, “We know that they work, but it can sometimes be a bit difficult to reconnect the links, so we’re back in the shop figuring out a better way to attach them so that it’s easier for the user.”

Wheeler had his own Chevelle on the rack outside of the shop for us to take a look at, and explained how these bars are designed. “Some sway bars have as many as fifteen bends in them to clear suspension components,” he told us.

Many classic cars didn’t come with sway bars, especially in the rear, so designing a bar that will clear all of the other components takes a lot of measuring and bending. Hellwig isn’t satisfied with just bolting a sway bar onto the car, and neither is Wheeler. It has to perform, and it has to be impressive before it’s shipped from their facility. Anything less, and it’s not a Hellwig Product [4].

Top: measurements are taken and there are steps in place to make sure that these springs and sway bars fit the template properly. Bottom: Hellwig's shipping department is almost as big as the rest of the shop, and they keep very busy.

Check out more exclusive pictures from our tour below: