Last year, Ford Racing Parts [1] started offering its X302 crate engine completely dressed with an intake manifold, carburetor and distributor for customers who don’t want to bother with shopping for those parts. The X302 is a direct-drop-in with a minimum of muss and fuss. For this year, the Ford performance team decided to tackle the next level of engine power – the 363ci Z363 bullet – and have been testing it with different intake manifold and carburetor selections in preparation for inclusion in the Ford Racing catalog.

“We’re looking at various ways to dress this long-block, and it’s the age-old argument of do you want to argue a peak horsepower number, or do you want to look at something that’s a bit more streetable?” Tom Detloff, Ford Racing engine engineer, tells EngineLabs [3]. “So what we do is test a number of different combinations before we just settle on one. If you look at our M-6007-Z363 long-block, the power numbers were achieved with a Holley [4] HP750 carburetor and Edelbrock [5] Super Victor intake manifold. That gets us a nice healthy 500 horsepower peak number, but for the guy who’s looking to drive this engine around on the street, we get questions all the time about what parts to use for the best streetability.”

“Previously, we’ve offered this long-block with the idea of letting the customer decide what to use for an intake and carburetor,” adds engine product manager Mike Delahaty. “But what we’ve found out is that there are a lot of customer out there that don’t want to fool around with choosing and jetting a carburetor. This way it’s one part number where the customer doesn’t have to worry about installing those final parts – the engine is much closer to being done and ready to use. The plan is to roll this idea across the rest of our crate engines as well.”

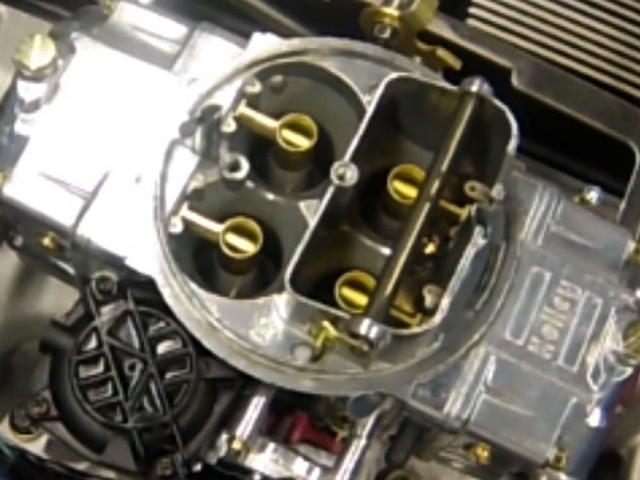

Priority for the Z363 package was building more low-end torque into the engine, and to that end, Edelbrock’s Performer RPM intake manifold, a standard Holley 750 cfm carburetor and MSD [6] 8596 billet distributor were chosen to complete the package.

“The Performer RPM cost us approximately 35 horsepower on the top end, but the good news is that it picked up 45 to 50 foot-pounds of torque downstairs. It makes right about 400 lb-ft from 3,000-6,000 rpm,” says Detloff.

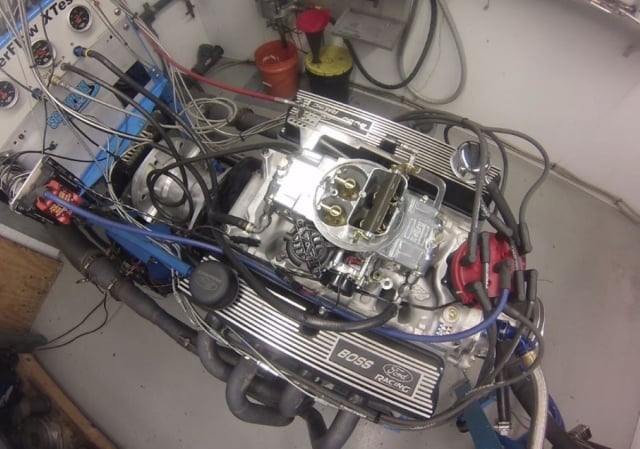

Left - With this engine, dozens of hours of testing were performed by the Ford Racing Parts team in an effort to identify the best solution for all-around horsepower. Right - An overhead shot of the engine on the dyno.

Other components include Ford Racing’s own Boss302 8.2-deck engine block bored to 4.125-inch, a 3.400-inch stroke SCAT [9] forged-steel crankshaft, SCAT forged I-beam connecting rods, Mahle [10] forged pistons and Ford Racing aluminum Z304 cylinder heads with 2.02-inch intake and 1.600-inch exhaust valves.

[11]“These engines have to fit a lot of applications – we have Mustang guys, Bronco guys, kit-car builders all using them. We strive to identify our true customer base, and that’s real important on the customer side of the business – what they want versus what we build could be very different,” Detloff explains.

[11]“These engines have to fit a lot of applications – we have Mustang guys, Bronco guys, kit-car builders all using them. We strive to identify our true customer base, and that’s real important on the customer side of the business – what they want versus what we build could be very different,” Detloff explains.

As the testing team led by Detloff has access to a dedicated dyno cell in the Ford Racing testing headquarters, they are constantly trying different parts on all of their crate engines, just to see what type of results will pop up. With OE-level data acquisition, there are reams of data to dissect at all different points of engine operation. “The great thing is that we have these resources available to us, and there’s a lot of stuff that goes on behind the curtain here that the customer will never see. Some of it never even makes it to the market, but we’re always trying to improve our products,” says Delahanty.