When it comes to restoring a vehicle and retaining the period-correct parts along with the matched engine parts that were on the car when it rolled off the assembly line, there are many challenges. But restoration expert Andrew Taylor, who is in the middle of finishing up this restoration for an unnamed customer, took every precaution possible during the rebuild process to ensure that the L36 engine in this 1967 Corvette appears original, while providing a substantial performance boost – although that wasn’t the original plan.

The car was purchased by the customer at the Houston Mecum auction back in April of 2014, and shipped to Taylor’s facility in Palm Springs, California. The car is a numbers-matching Corvette Convertible boasting only 85,853 miles, a factory four-speed manual transmission, and side-pipe exhaust, and was factory equipped with an L36 390 horsepower 427 cubic-inch engine.

Other options that make it rather rare include the factory tinted glass, leather headrests, soft convertible top (with auxiliary hardtop), air conditioning, along with power steering, brakes, and windows. The car is finished in Ermine White with a blue stinger on the hood and a bright blue leather interior.

“We drove it for a few weeks when we first got it here, and before long the engine began making knocking noises. I cut open the oil filter and found bearing material, so we knew the engine needed an overhaul. After pulling the motor and tearing it down I documented all the damaged parts. All main bearings showed massive deterioration, and there were multiple spun rod bearings. Cylinder number seven’s top piston ring was broken and all cylinders showed bad ring wear. The crankshaft was already ground .030-inch on the main and rod journals. It was clear this motor had been rebuilt many times and the crank was at the end of its life,” says Taylor.

Material in the oil filter, wrecked bearings, and a broken piston ring necessitated an engine rebuild just weeks after purchasing this car.

With the damaged engine in hand, Taylor and his customer set out to repair it with a number of goals in mind. Repairing an engine that’s 47 years old presents challenges of the highest order.

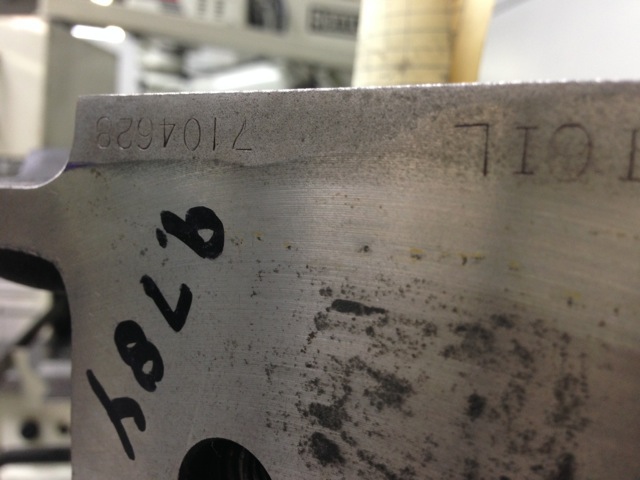

Great care was taken to preserve the cylinder head and block identification numbers during the rebuild process.

Once the engine was removed from the car, a number of issues were found that complicated the restoration process. Working with the original block and cylinder heads presented a challenge. To retain the original stamped VIN numbers on the block’s deck surface was difficult; Taylor tells us that many restorers will cut those off during the decking process and re-stamp them, but he feels that keeping the original numbers intact is the correct way to go about the restoration.

“We wanted to make this car a reliable, durable, and overall fun driver for the great California weather. Since it is a numbers matching engine and drivetrain, and everything else is mostly original, we tried to keep as much of that originality as possible, not just for the owner and me, but for the community and future generations. And of course we wanted to give it a little extra performance. No expense spared, only the best parts have been used. We expect this car to do it all, from trips to the store to cruise nights, car shows, and driving events,” he explains.

During the build process, instead of re-using all of the stock parts inside, he turned to a number of aftermarket manufacturers to provide a large upgrade in performance while retaining the factory-installed block and cylinder heads. Crower supplied a forged 3.76-inch stroke crankshaft to match the stock dimensions, along with a set of the company’s 6.125-inch forged connecting rods. A set of ICON forged pistons featuring a 10.2cc dome was used, with a 4.310-inch bore dimension – .060-inch larger than the factory bore. Clevite bearings assure the assembly spins freely in the block. In a nod to the 91-octane pump gas available in California, Taylor set the compression ratio at 9.98:1 instead of the stock 10.25:1 ratio.

The new forged crankshaft from Crower is capable of handing 2,500 horsepower – a bit of overkill as this Corvette will never see that power level, but it was deemed the best product for the situation at hand. It was balanced for smooth operation and a trouble-free life.

In addition, performing a valve job to allow the heads to use larger valves was challenging, as the cylinder heads couldn’t be cut for hardened valve seats without breaking into the water passages.

Despite those difficulties, the heads were machined to make use of oversized Manley intake and exhaust valves. A full complement of valvetrain gear from COMP Cams was used, including their Ultra Pro Magnum 1.7:1-ratio roller rocker arms, their hydraulic roller lifters, new pushrods and valvesprings, along with a double-roller timing set.

COMP Cams valvetrain gear was used, and two camshafts were tested on the dyno to find the most streetable combination.

The cylinder heads were also treated to a custom port job and gasket match, and flow 318 cfm at .600-inch lift. An MSD Pro Billet distributor and 6AL ignition box were used in conjunction with the Holley 4150 HP-series carburetor to light the fire within the cylinders.

“Once everything was assembled and we started break-in on the engine dyno, a crack developed on the passenger side of the block below the deck surface, slowly leaking water. It was a heartbreaker after all the work we had put into it at that point,” says Taylor.

A setback like that could be devastating to many restoration efforts; the expense and time associated with a build like this are not for the faint-of-heart, but he had a solution.

Note the cold-stitch repair on the outer side of the block – this stopped a water leak and should last the life of the engine.

“Fortunately cast iron repair techniques can do some pretty amazing things these days. After pulling the motor off the dyno and repairing the block with a stitching method (while still fully assembled), we were able to get some great power numbers,” says Taylor.

During the dyno process, two camshafts were tested to determine which would be the best solution for the intended goals. The first was a grind that Taylor knew from previous experience would make good power, and did so, turning the dyno to 530 horsepower and 530 lb.-ft. of torque, but only making between 10-11 inches of vacuum at idle.

With the car requiring decent around-town manners to fulfill its intentions, the second camshaft was slid into the block, and after more dyno testing, it was determined that this piece was a much better fit. The end result was 527 horsepower and 517 lb.-ft. of torque, but 14-15 inches of vacuum at idle. By 3,000 RPM, the engine is up over 500 lb.-ft.

“I am putting the finishing touches on the engine bay as we speak, and I expect to have it running in the next week or two,” says Taylor. We’ll bet that one happy customer is anxiously awaiting the end of the process.