[1]

[1]

Our 2011 Mustang GT, Project Wild E. Coyote [2] has been a test bed for a variety of parts, including suspension. We set a goal early on with this car to achieve 10-second quarter-mile time slips and at least 1.0 g of grip on the skid-pad.

As we have been securing things in the horsepower department lately with our new turbocharged, built Coyote engine [3], it’s time again to turn our attention to the car’s suspension. To try out and test a new suspension combination, we turned to Kenny Brown Performance [4]. Kenny Brown has been cranking out championship-winning suspension systems for Mustangs for over 25 years. Brown himself has over 40 years experience in the racing world, building everything from Trans Am winning muscle cars to customer cars that offer better handling for the street or the track. Now apart of the Heidts Automotive Group [5], Kenny is part of the ultimate partnership of engineering and manufacturing

[6]

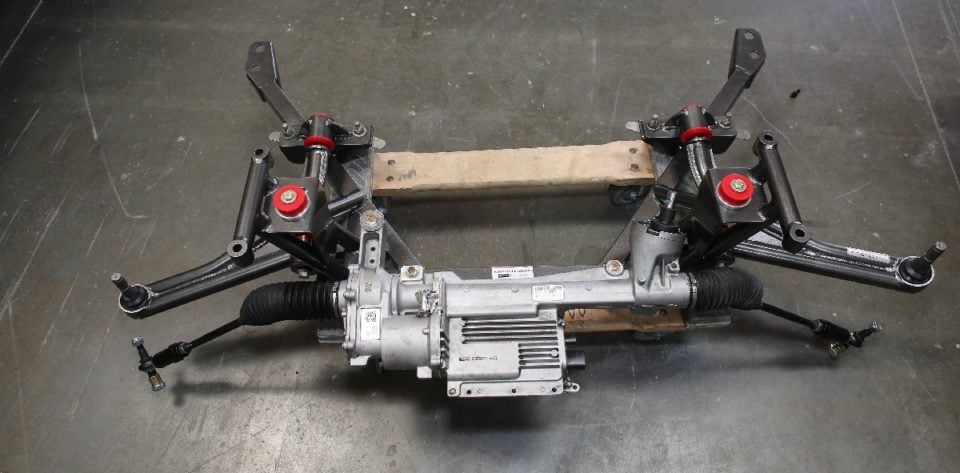

[6]The result of over 25 years of late model Mustang suspension tuning and 40-plus years in racing, the Kenny Brown Performance AGS 4.0 suspension system should give Wild E Coyote the grip needed to meet our handling goals.

Born on the Track

Brown’s approach to Mustang handling is to do the engineering, research, and development of parts for the race cars first. “I create the car, then take the parts from it and put them on the shelf,” says Brown, who prefers this approach over simply creating parts first, selling them, and trying to make them work on racing applications.

Brown’s decades of experience tuning Mustang chassis has resulted in the current AGS 4.0 suspension system for the S197 Mustang. The 4.0 means this is the fourth generation of that Advanced Geometry Suspension system, which began back in the early 1980’s when Brown developed suspensions for Steve Saleen.

We had already removed the front bumper and grille from Wild E Coyote. Left: We disconnected the front sway bar, control arms from their ball joints, and outer tie rod ends. Center Left and Right: We then removed the core support which will also be replaced as part of the K-member kit. Right: With the engine supported above we removed the bolts retaining the K-member.

Regarding the S197 Mustang chassis Brown says, “Ford gave us the elements we needed with this car to get the suspension right.” Getting it right means maximizing the tire’s contact patch area, as well as improving suspension geometry, and roll center. Understanding the Mustang’s strengths and weaknesses in terms of handling is what allows KB to create cars and suspension systems that handle extremely well.

[11]

[11]Using our lift we simultaneously removed the original front suspension, along with our worn out and tired factory Coyote engine.

Front Engineering

In racing most of your passing happens in the turns, so if you can stay on the power longer, brake later, and get back in the throttle sooner, you now have the advantage. -Kenny Brown, Kenny Brown Performance

According to Brown the front roll center in the S197 Mustang is actually too low for the car to behave properly on the track. This combined with the factory suspension geometry causes the Mustang to push in the corners. By raising the roll center in the front, and fixing the other geometry issues, the car is able to turn through the corner and is more balanced, alleviating the push.

Left: The Kenny Brown Super Grip front control arm modules change front suspension geometry, raising the front roll center for improved braking and turning. Right: We installed the control arms on the K-member before putting the K-member on the car.

K-Member

Kenny Brown Performance engineers their suspension systems for the track first. Up front the K-member, part number KB-49710 is revised to not only shed some weight, but to also provide added strength. The KB K-member is constructed from 1.5-inch .120-inch wall steel tubing.

The K-member aligns the front spring buckets and also adds more caster to the front suspension – improving cornering grip, and makes the KB control arms a direct bolt on, with no other modifications necessary. The K-member can be paired with Kenny Brown’s front core support, which is stronger and lighter than the factory stamped steel part.

Left: Our stock K-member and control arms weighed in at nearly 77 pounds. Right: Our KB K-member with control arms attached weighs slightly over 57 pounds.

Control Arms

The KB Super Grip front control arms are where the majority of the front suspension geometry changes are made, ours are part number KB-49731 for 2010-2014 Mustangs. They are set up so that the bushings now run parallel to the centerline. These control arms completely change the front suspension geometry adding anti-dive, as well as better caster and camber gains for improved cornering. They also raise the front roll center, which according to Brown is necessary for proper Mustang handling. According to KB these are also the strongest front lower control arms on the market for the S197 Mustang.

Left: It is easier to transfer the electric power steering unit to the K-member on the ground than in the car. Center Left: We installed our new long-block on the K-member with new engine mounts so we could put everything together as an assembly. There are two engine mounting locations on the KB K-member - stock or one inch set back. Center Right and Right: With everything in place our new long-block and K-member were wheeled into place and the car was lowered onto them.

Tracking True

[20]

[20]This Baer Tracker bump steer kit eliminates bump steer, and allows us to set the front tie rod ends parallel to the ground. This is a must for lowered cars, to achieve proper handling.

We also installed a bump steer kit from Baer [21] part number 3261008. This Baer Tracker system features spherical joints at each end, and is adjustable. This is the same system used on a variety of track cars, and will ensure our tie rod ends stay parallel, preventing bump steer. A bump steer system is a must-have for nearly any lowered vehicle, and definitely for a car that will see track time where suspension settings are crucial to cornering capability.

The Baer Tracker bump steer kit installs in place of our factory outer tie rod ends. It is then adjusted to set the toe properly, and get bump steer corrected. Setting bump steer is a pretty complicated process, but Brown mentions of a cheaper way that will get you pretty close, “Set the mid-point height of the tie rod end’s joint at the same height as the mid-point of the lower control arm ball joint will get you pretty close.”

Left: With our K-member bolted into place we also secured everything back together in our front suspension. Right: We then proceeded to install the front radiator support and sway bar mount.

Rear Engineering

All of that front end engineering isn’t any good if the rear of the car doesn’t behave properly as well. Since the Mustang is still a live rear axle car, the rear suspension and axle become unsettled during hard cornering. This means that a driver must wait longer to get back into the power. As Brown pointed out earlier, with most passing happening in the corners. That wait can cost racers a position, getting the back of the car settled, as well as getting the car to rotate properly through a turn is critical to maintaining position, or better yet overtaking a competitor.

[24]

[24]Our Kenny Brown Performance rear suspension pieces consist of their street/sport single adjustable rear lower control arms, U-link, rear upper control arm module, and rear roll center relocation kit with heavy duty panhard bar.

Panhard Bar

The rear roll center is the point where the panhard bar crosses the center of the axle, by moving the panhard bar down you lower the rear roll center of the car and improve the handling. -Kenny Brown, Kenny Brown Performance

“The rear roll center is the point where the panhard bar crosses the center of the axle, by moving the panhard bar down you lower the rear roll center of the car and improve the handling,” says Brown. “Lowering the rear roll center lines up the rear axle better with the chassis, and changes the handling dynamics of the car. This combined with the other KB AGS 4.0 components helps settle the rear end of the car, allowing it to rotate and exit a corner faster, and let the driver get back on the throttle earlier.” Longer blasts on the throttle that are able to occur sooner equate to faster corner exits, and higher speeds on the straight-aways. When the chassis reacts properly to braking action, that then helps the driver turn the car properly and maintain control. It all adds up to faster lap times, or some very entertaining afternoons running favorite back roads.

Left: The U-link, rear upper control arm module, replaces the weak factory link. It is a different length than factory and features and adjustable rod end eliminating deflection. Center: To replace the upper control arm the rear seat must be removed to gain access to the mounting bracket bolts. Right: With everything in place we finish the upper control arm off by attaching it to the rear axle housing.

Rear Lower Control Arms

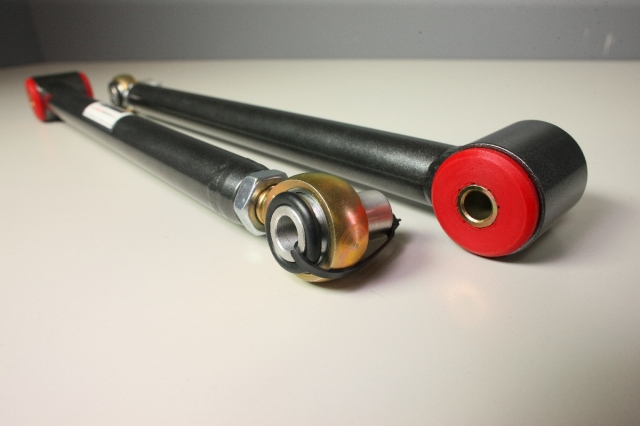

The rear lower control arms in the KB AGS 4.0 suspension system further correct the rear suspension geometry. We spec’d the street/sport control arms, which feature a single adjustable rod end on the chassis end, and a high performance urethane bushing on the axle end, these are part number KB-28661.

[28]

[28]The rear lower control arms feature an adjustable rod end on the chassis side, and a urethane bushing on the axle side.

The bushings help to eliminate deflection caused by the compliance that is built into the factory lower control arm bushings, while offering adjustability of the rear axle alignment and pinion angle. The inherent U-shape of the Kenny Brown upper control arm also increases clearance on severely lowered Mustangs.

Normally these lower control arms would be paired with KB’s anti-squat brackets to optimize instant center. However, our Moser M9 housing already has adjustable mounting points for the rear lower control arms. In this case we already have anti-squat options built into the housing mounting points.

Left: To help get the lower control arms as close to the proper pinion angle as possible we adjusted them to the length of the arms that were previously installed, the rod end goes to the chassis side. Right: Since we already have adjustable mounting brackets on our M9 axle housing, we don't need the KB anti-squat brackets.

Rear Upper Control Arm

Panhard Vs Watts-Link

So why does KB stick with a panhard bar rather than switch to a Watts-link? It all goes back to correcting the rear roll center. “The problem with a Watts-link is that where the pivot point is located on the rear axle, is also where the rear roll center is,” says Brown. On a dedicated race car, this pivot point can easily be located on the bottom of the rear differential. However, on a street going car this requires considerable fabrication, which the typical enthusiast may not have access to. It also decreases ground clearance to locate the pivot point so low. The KB heavy duty panhard bar and Roll Center Relocation kit becomes an easier to install and effective solution for street going enthusiasts, and is installed and raced on the KB GT4 package vehicles.

No Rear Sway

With all of these upgrades to the rear suspension, many readers might have questions regarding the rear sway bar. With the use of the AGS 4.0 suspension, the rear sway bar is actually no longer needed and is removed. This may sound like a step in the wrong direction, as rear sway bars are often necessary for properly balanced rear handling, however, Brown explains, “The purpose of the rear sway bar is to transfer load back to the unloaded wheel. Correcting the rear suspension geometry and roll center eliminates the need for a rear sway bar.”

With the rear roll center, anti-squat, and instant center migration corrected, the rear sway bar essentially becomes a piece of extra weight that can be removed from the back of the car.

Left: With our other panhard bar out of the way we first installed the panhard bar relocation bracket on the chassis. Center Left: We then installed the panhard bar reinforcement. Center Right: Next we installed the panhard bar bracket on the rear axle housing. Right: With our brackets in place we adjusted the length of the panhard bar and secured it in position.

Installation

Installing the parts is literally a bolt on affair. Since we have the engine out of Wild E Coyote for our new turbo-fed mill to go in, removal of the K-member does not require supporting the old engine. We shaved almost 20 pounds of weight off the front of the car – our stock K-member and A-arms weighed over 76 pounds – while our new KB parts weighed just 57. Making things even easier we set our long-block on our new K-member and installed everything together, ensuring we didn’t have to drop the engine in from the top.

Left: With all of our parts in position we can now set the rear pinion angle. Right: A sway bar is essentially a spring that transfers load from the unloaded to the loaded wheel. With the corrections made by the AGS 4.0 suspension system to the rear geometry the rear sway bar is no longer necessary.

In the rear of the car, the most tedious part of the installation is the upper control arm, simply because it requires the removal of the back seat to gain access to the mounting bolts. The rest of the pats simply swap in place of the originals, including the panhard bar, which has a simple bolt in mounting system.

Aside from setting our rear pinion angle, there are no adjustments to be made to our rear suspension. Brown says, “We try to do all the engineering for the customer so that they can spend their days making laps at the track, rather than trying to figure out adjustments.”

For the moment we’re still running our Ford Racing struts, shocks, and springs, though Brown is trying to convince us to make a switch to their Koni spec pieces, something we may go to in the future. For now we can’t wait to wrap up the rest of the changes and get Wild E Coyote back on the road, and more importantly to the track for the payoff on this new suspension system.

Parts Used

[38]

[38]We can’t wait to get Wild E. Coyote back out on the twisties. Already we notice that the front end turns in quicker, without pushing at all. The rear of the car stays planted and truly works harmoniously as a total suspension package.

Kenny Brown Performance

- K-member KB-49710

- Super Grip Front Control Arms: KB-49731

- Street/Sport Single Adjustable Rear Lower Control Arms: KB-28661

- U-Link, Rear Upper Control Arm Module: KB-28675

- Roll Center Relocation Kit With Heavy Duty Double Adjustable Panhard Bar: KB-28620

Baer

- Baer Tracker Tie Rod End/Bump-Steer Set: 3261008