[1]

[1]

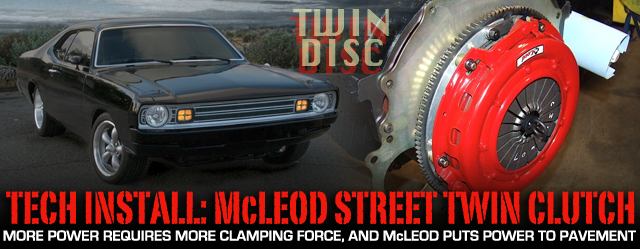

We’ve brought you a feature on this Dodge Demon [2] before from Viau Motorsports [3], and while we felt that the car was already a potent street machine, car owner Mark Viau told us that he had other plans for the Demon. We gave it a test drive; there was plenty of power in the small block 340, and the factory four-speed was more than capable of getting that power to the rear. But Viau wanted to get this car out on the track and do some road racing, and for anyone who knows Viau that means more power.

With more power, comes the potential of not being able to transmit that power through the transmission because of a clutch system that doesn’t meet up to the challenge. A standard clutch might be fine for a regular driver with 300-400 horsepower, but not for this Demon – burning out a clutch because the engine is producing too much power isn’t within the scope of things.

The Demon is not only going to get a fresh engine build, but a new 5-speed transmission is part of the upgrade – and that means it’s time for a new clutch, also. Viau looked to McLeod Racing [5] for a Street Twin clutch kit to help put power to pavement when the go-pedal is mashed.

The first part of this project was to build a new small block that would see well over 500 ponies at the crank. Using some of the best components in the performance industry, Viau set out to put some more muscle into this musclecar.

That also meant that the transmission needed to be able to keep all those ponies in check without worrying about it breaking down on him when he puts the hammer down. Viau stepped up his game with the Tremec [6] TKO 5-speed transmission. But before the trans is bolted to the engine block, some modifications were in order because Viau wanted components that can take the abuse.

The potent Mopar small-block and the popular Tremec transmission.

The Tremec is already a stout transmission, and with the A-body’s small tunnel we knew a 6-speed was out of the question. Still, the 5-speed Tremec went through a few modifications by Geoff Gerko at Gerko Enterprises [9] to prep the trans for the kind of power and action the car is going to see in the coming months. The TKO has upgraded syncros, shift forks and some surface finishing to make it perform better and increase its torque capacity; it has also been modified slightly to fit into the small and narrow tunnel in the Demon. These changes will help the TKO handle the kind of power that’s being fed to the transmission.

The new engine was built with racing in mind, pushing out over 500 horsepower on the dyno at Westech Performance [10] in Mira Loma, California. With the Tremec TKO getting massaged by Gerko Enterprises in Lancaster, California, we knew the trans could handle the power, and Viau needed a performance clutch that handle the power, too. For that task, McLeod Racing’s Street Twin clutch [11] with an aluminum flywheel offers the performance and clamping force that is desired.

McLeod’s Twin-disc Clutch

When you’re putting this kind of power through the gears, making sure you get enough clamping force can be an issue. McLeod Racing has a solution for the Demon by way of their Street Twin Clutch Kit.

Twin-disc clutches aren’t new to the scene, though. As a matter of fact, McLeod was one of the first companies to bring a twin-disc clutch to the aftermarket in 1974. McLeod has been around for over four decades providing the aftermarket with quality performance clutches.

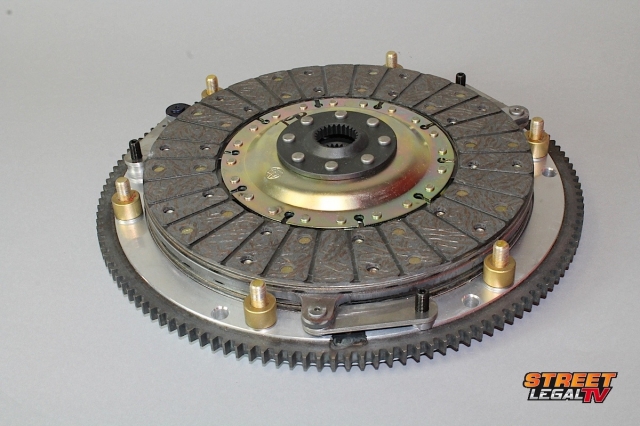

The real advantage of the twin-disc clutch is that you can double the clamping force without doubling the pedal pressure. Between two friction discs rides a floater plate, which is typically a steel plate that works much like your flywheel does.

Both friction discs will clamp onto this floater plate when the clutch is engaged; with the front disc gripping the flywheel and the rear disc gripping the pressure plate. Instead of two surfaces making contact, you have four surfaces providing the clamping duties.

When To Use a Twin-disc Clutch

The need for a twin-disc clutch arises when horsepower is increased and clamping force needs to be increased as well. If you’ve ever had a clutch slip on you, then you know that it’s not getting the necessary clamping force to propel your car forward. With a high horsepower engine in a musclecar like this Demon, a stock, single disc clutch could work just fine, but all of that horsepower can wear out the clutch prematurely. The lower clamping forces on a single-disc clutch will allow the clutch to slip a little more than with a twin-disc clutch, and increasing the clamping force allows the car to hook up much better. Too much power and not enough clutch is a recipe for failure.

The clutch arrives assembled, and care should be taken to reassemble in the same manner. The friction discs are marked for easy assembly.

With low to moderate horsepower engines, a single-disc clutch works just fine. Knowing that a twin-disc clutch provides double the clamping force, however, is not always the best recipe for lower horsepower applications.

Installing the improper clutch on your car can easily lighten your wallet, and cause drivability problems. -Billy Mieczkowski

Billy Mieczkowski of McLeod Racing, said, “Installing the improper clutch on your car can easily lighten your wallet, and cause drivability problems. We prefer that customers call us first and let us set them up with the proper clutch for their application.”

A twin-disc clutch in a car with lower power is too much clutch and can give you a heavier than normal pedal feel. But having in excess of 500 horsepower behind that flywheel and engaging the clutch, that additional clamping force will keep the clutch from slipping.

With cars like the Demon, the rear tires are a bit larger, and quite a bit softer than what originally came on the car in 1972. That creates a lot of resistance in the drivetrain, and a single disc will typically slip more than you want it to when you engage the clutch.

The aluminum flywheel reduces weight, but it still has a steel insert for the contact surface. Otherwise, the clutch would destroy the flywheel in a hurry.

There are also more things to consider when you’re ordering your clutch. This all depends on the type of driving you do, where you drive your car the most, whether you race it at the dragstrip or the autocross, and of course, how often you drive your car.

If your car is a daily driver and you’re often in bumper-to-bumper traffic, you will definitely want a clutch that suits your needs. The bigger is better way of going about things doesn’t work for a clutch, and that’s why Mieczkowski encourages customers to call first and get the proper clutch for their application.

As busy as it looks, there are really only a few extra parts for the Street Twin clutch. [19]

[19]

Mieczkowski said, “If you’re running a twin-disc clutch, you should be above 500 horsepower or you might have too much clutch for your vehicle. A twin-disc clutch is harder to drive on a street car, and you will need to make sure you have the revolutions up when you’re going from stop light to stop light.”

If you’re running a twin-disc clutch, you should be above 500 horsepower or you might have too much clutch for your vehicle. -Mieczkowski

Of course, driving a manual trans in traffic with a twin-disc clutch can be a bit of a chore, and it might take a little bit to get used to. It’s not about the inability to drive a manual trans, it’s the lower rpms when in bumper-to-bumper traffic and finding the right balance of engine rpm and releasing the clutch.

For spirited driving, having that additional clamping force is a great combination – especially in the autocross where engine revs are typically higher anyway.

Installing The Street Twin Clutch Kit

As we mentioned, a twin-disc clutch has two discs, and in between those discs is the floater plate. The floater plate provides two additional surfaces for the clutch friction discs to clamp to. This floater plate, and the extra friction disc, are two of the additional components that a Street Twin clutch has over McLeod’s single disc clutches. With that exception, both a single and twin-disc clutch work essentially the same way: when you press the pedal, the clamping force is relieved, when you let up on the pedal the clamping force is applied.

As the clutch is engaged (pedal out) the spring steel tabs allow some flexibility so that the entire clutch assembly can clamp down onto the flywheel. The two friction discs and the floater plate are sandwiched between the flywheel and the pressure plate. The flywheel, floater disc, and the clutch cover are all bolted together to keep the four mating surfaces rotating with the engine; the two friction discs are installed on either side of the floater, and they ride on the splined input shaft on the transmission.

The floater plate rides between the two friction discs, providing two additional clamping surfaces to the clutch. the three straps allow the floater plate some flexibility when the clutch is engaged.

The floater plate must ride between the two discs without hanging up on either disc when the clutch is disengaged, otherwise one side of a friction disc can wear prematurely. To enable the floater to ride between the two friction discs it must be spaced properly, and yet still be able to move slightly when the clutch is engaged.

You can see the three straps on the floater itself, these straps are spring steel and they allow the floater to ride between the discs when the clutch is not engaged. Because they are spring steel, they flex a little and allow the floater to be clamped between the two friction discs. If the floater did not have these flexible straps, clamping force would be compromised and the clutch would not function properly.

While the floater is fixed in a rotational manner to the flywheel, spacers are used to space it properly between the two friction discs. For this reason, the clutch should be assembled exactly as it was when you received it, and paying close attention to spacers and the markings is paramount. The flywheel needs to be bolted to the crankshaft first, then the clutch is assembled according to the labels on each component, with the proper orientation. Care should be taken when you disassemble it – guessing is not an option.

After installing the pilot bearing, the clutch is assembled onto the engine in the same order that it came apart, paying close attention to the shims and alignment.

Flywheel Choices for the Street Twin Clutch

The Street Twin Clutch Kit is available with a steel or aluminum flywheel, and each has a purpose. The rotational mass of a steel flywheel helps keep the engine revved up between shifts, and the light weight of the aluminum flywheel allows for quicker revs in a racing environment. With a heavy flywheel, clutch engagement might be a little easier on the clutch because of rotational mass; an aluminum flywheel would require more throttle to keep the revs up between shifts.

Mieczkowski said, “The steel flywheel is more like your stock applications, there is stored energy when the engine is idling and that allows the clutch to grab the flywheel better in traffic when going from stoplight to stoplight. With the aluminum flywheel, there isn’t any stored energy and with lower engine speeds it’s easier to stall the car at traffic lights.”

[29]

[29]The McLeod Street Twin clutch and aluminum flywheel installed, and ready for the Tremec 5-speed to be installed.

So what does all that mean with regards to the aluminum flywheel? It means that you need to keep the engine revs a little higher when you’re going from stoplight to stoplight. Just as you will see cars in a racing environment rev higher at launch, that’s what you’ll need to do with a street car with an aluminum flywheel. For this reason, Mieczkowski recommends a steel flywheel for street use, and an aluminum flywheel for racing applications. An aluminum flywheel allows for quicker revs, which is great for a racing environment, but no so much for the street, especially in traffic.

The Hurst stick shift provides a good feel, and the Demon is awesome from any angle.

Driving Impressions

The McLeod Street Twin clutch proved to be a great combination with the built engine and the Tremec transmission. Even though Viau chose to use a mechanical clutch, due to limited firewall real estate, the feel is soft and the clutch allows for comfortable driving.

[32]With the new clutch, engine and trans installed, the first order of business was to put some miles on the new drivetrain, and Viau set out for a car show in the area, putting more than 100 miles on the car in the process. The Street Twin clutch takes a little bit to get used to, but Viau is no stranger to high performance vehicles and this combination has proven to be just what the Demon needed to put power to gears – and to get that power to the pavement.

[32]With the new clutch, engine and trans installed, the first order of business was to put some miles on the new drivetrain, and Viau set out for a car show in the area, putting more than 100 miles on the car in the process. The Street Twin clutch takes a little bit to get used to, but Viau is no stranger to high performance vehicles and this combination has proven to be just what the Demon needed to put power to gears – and to get that power to the pavement.

Viau said, “The clutch is very smooth and easy to operate, but once it’s engaged it is very responsive. In both city driving and a long cruise, the best part was that I didn’t suffer from having a sore knee from repeated clutch operation,

If you’ve been contemplating a performance clutch from McLeod’s website [5], but you’re not sure which is the right one, don’t hesitate to give them a call. Because, as Mieczkowski said – they would rather you buy the right clutch to fit your application instead of buying one based on price.

[33]

[33]First trip out with the new McLeod Street Twin clutch was a nice 1-hour+ drive to show off the Demon. Everything performed flawlessly, and the trip was enjoyable.