If there’s one Ford product that even GM and Mopar owners don’t mind using, it’s the 9-inch rear axle. Introduced in 1957 and used up through most of the ‘80s, the Ford 9-inch is a favorite swap into hot rods, drag cars, wicked street machines, stock cars and even off-road vehicles. In today’s high-performance applications, however, there’s rarely a single Ford-built part in a 9-inch rear end. Strange Engineering, along with other aftermarket companies, have embraced this iconic drivetrain component and developed an extensive line of parts and complete assemblies that leverage the strengths of the original 9-inch design while improving on durability, flexibility and performance.

Strange’s catalog of 9-inch products is one of the most extensive on the market. Ranging from replacement parts up to a wide selection of race-ready axle assemblies that are competitive in many forms of motorsport in addition to serving as strong foundations for a variety of street cars.

“What makes it so popular now are the options available,” says J.C. Cascio, sales and marketing manager at Strange Engineering, which is celebrating its 50th anniversary this year. “There’s also a strength advantage when compared to other axles.”

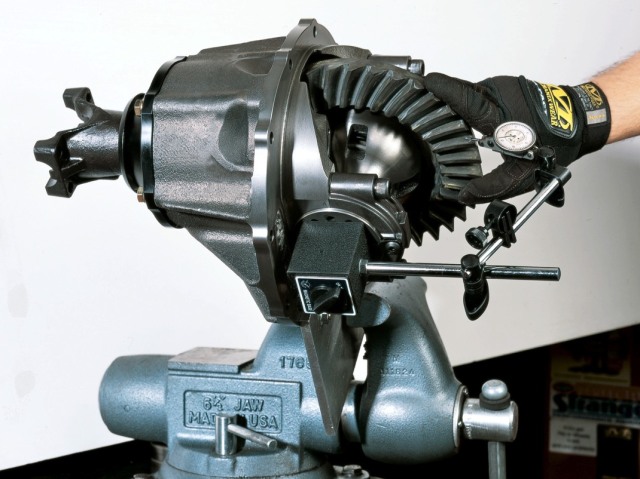

The 9-inch is also much easier to service. The center section supporting the differential can be pulled out of the housing and placed on a workbench for repairs or gear swaps. This option speeds up the service compared to axles where the differential is assembled inside the housing.

Where the strength lies

I’m real skeptical about attaching horsepower numbers to the discussion because a 6,000-pound car making 400 horsepower will be harder on parts than a 1,500-pound car making 1,000 horsepower. – JC Casico, Strange Engineering

Not that other axles aren’t popular for their own reasons. The Dana 60 is often favored in trucks and off-road vehicles, and the GM 12-bolt is found in millions of muscle cars.

“But race teams that change ratios often and have a 9-inch don’t have to put the car up on a rack or pull the entire rear end out of the car,” says Cascio.

Much of the inherent strength in the 9-inch comes from the extra support given to the pinion gear. In addition to a pair of bearings in the pinion support located in the front part of the case, there is a “tail” bearing in the back of the case that supports the nose of the pinion.

“This definitely limits the amount of deflection within the case,” says Cascio.

The 9-inch has a reputation for strength, and one of the key factors is the rear pinion support built into the case. You can see the nose of the pinion gear just off to the right of the left cap.

There is a downside to the 9-inch in that it can absorb a little more power meant for the rear wheels than some other designs with similar-sized ring gears, such as a 12-bolt or 8.8-inch Ford. Strange Engineering participated in tests with Ford a number of years ago to gather data and analyze this loss.

“If you compare similar setups, there can be a three to four percent drop in horsepower with a 9-inch Ford,” says Cascio. “That being said, however, that’s where we start getting into some of the options that can limit that loss, such as ball bearings or treating the bearings and gear sets to lower the friction.”

Sourcing the power drop

The offset between the pinion centerline and the ring-gear centerline is the culprit in this power-grabbing dynamic. With the Ford there is a 2.25-inch difference while the 12-bolt is only 1.5 inch. The reduced distance helps limit the resistance between the pinion and ring gears. The Dana 60 has an even better relationship between the gears but also has a much heavier differential to sling around, so there’s somewhat of a push in efficiency.

Since the removable center section is the key selling point for the 9-inch design, we’ve compiled a comprehensive look into the assemblies and options available from Strange Engineering. These center sections can be ordered with axle housings specific to the race or street application, or installed on an existing housing – whether it’s a factory or aftermarket unit. Of couse, there may be some restrictions – and that’s why consulting with one of the company’s tech representatives is essential to ordering a center section that meets the performance and budget needs of the vehicle owner.

Proper Setup and Installation

Differentials are finicky when it comes to torque specs and settings. Be sure to follow all the instructions that come with components as well as assembled center sections. Some differentials require lubricant modifiers. There’s also a specific break-in procedure and directions on setting up load bolts, if so equipped.

Strange offers five different styles of center sections — two iron and three aluminum. Not all are designed for the street, and not all are suitable for some racing venues.

“The center sections all fall into their different niches, and there is crossover between them,” says Cascio. “But we handle all applications on a case-by-case basis.”

There are obvious matches, such as a 400-horsepower street car getting the S-Series iron case and a Pro Mod car working with the intricately designed aluminum Ultra case. In between, however, there are compromises that often have to be considered.

“These days there are a lot of high-horsepower street/drag cars and you have to make sure you cover that gray area with a part that will work for both,” says Cascio, noting that it’s rare to ‘overbuild’ the structural components of a rear-end assembly. “I’ve had guys who want to put an all-out race application on the street and it’s not a downside for strength. But definitely, if you put a spool on a street car, then the car’s drivability will suffer.”

Understanding horsepower and weight relationship

Decisions can’t be made solely on the basis of vehicle weight or engine horsepower. It’s a combination of those factors plus other variables that enter into the final recommendation.

“I’m real skeptical about attaching horsepower numbers to the discussion because a 6,000-pound car making 400 horsepower will be harder on parts than a 1,500-pound car making 1,000 horsepower,” says Cascio. “When people ask about horsepower limitation, it really depends on the application. A car making 1,000 horsepower with street tires will just spin the tires, so it’s forgiving on parts. When the car starts hooking with a drag radial or slick, that really stresses the driveline.”

Each of the five cases from Strange Engineering was designed using computer analysis and simulation programs to test the structural integrity and optimize the configuration. It’s very easy to distinguish between the five cases, due to the different rib elements and pinion-support designs.

“It’s still form follows function in trying to keep everything light,” says Cascio. “And also make sure there are enough clearances and rigidity.”

Custom fabricated housings are available for the 9-inch sections from Strange Engneering. They can be ordered with brakes and trussed for extreme duty. Below: Bare housings, with and without axle tubes, are available for shops that need to fabricate rear axles for specific applications.

While Strange conducts some lab tests, much of the validation is handled at the track.

“We do some deflection testing, but really the R&D is done on the vehicle,” adds Cascio. “There’s a lot of field testing and tweaking based off that. We work with a number of race teams that will test the product and we’ll make changes accordingly.”

Strange Engineering 9-inch products

The following is a closer look at the five case designs and associated components that make up the complete assemblies.

Views of a bare and assembled S-Series case.

S-series Iron

The S-series case is designed primarily for street use and occasional trips to the track, depending on the application. Stronger than a factory unit, it’s available with two bore sizes: 3.062-inch for 28-, 31- or 33-spline axles and 3.250-inch for 35- or 40-spline axles.

“This case has a radial-rib design to make it stand out from our other cases,” says Cascio. “These radial ribs provide increased strength and rigidity.”

The S-series provides better clearances for limited-slip differentials (LSD) than dedicated race cases. It comes with a nodular iron Daytona pinion support but a forged aluminum pinion support is optional when a full assembly is ordered. There are also many options when ordering assemblies for the gear set, spool or LSD and yoke design.

Pro Nodular Iron

Constructed from D4515 nodular iron, the Pro case features forged chromoly caps and a reinforced tail-bearing area. Again, two bores sizes are available to accommodate axles from 28- to 40-spline.

“The Pro iron case is virtually indestructible,” says Cascio. “While the S-series is recommended for street/strip use, the Pro case is for higher horsepower street and drag racing.”

Pro cases can be set up with a choice of spools or LSDs and with the appropriate yoke or coupler. They’re also ready to accept a choice of gear sets. Finally, the Pro cases come with either an iron or aluminum pinion support.

Two views of the Pro nodular iron case.

Lightweight Aluminum

Designed primarily for vehicles under 2,600 pounds, The LW case can be ordered in natural or polish finished.

“Of course, horsepower factors into the limitations for this case,” says Cascio. “The main benefit is weight. It’s 20 pounds lighter than a Pro iron case. The potential issue is that you’ll get more deflection with a heavier car or one with higher horsepower, and that can take away from gear life.”

The LW case can be set up for street or strip, depending on the application, and can be ordered with numerous choices for spools, LSDs, gear sets, yokes and couplers – although there may be some limitations for spline count on the axles. Most applications use the aluminum pinion support, but iron supports are available.

Pro Heavy Duty Aluminum

The Pro HD case is new and built for higher horsepower cars and heavier street-car applications.

“This case can be used with LSDs or spools, so it’s an all-around case,” says Cascio. “People looking to save a little weight, they’ll spend a little more money but it’s a case that’s flexible in application.”

Three views of the Pro heavy-duty aluminum case.

The case is constructed from 206-T4 aluminum and designed with cap bolts that go through the face of the case for additional strength. There’s also a unique billet pinion support held with 7/16-inch hardware. All the relevant options for gear sets, spools, LSDs, yokes, and couplers are available in the assembled packages.

“It’s one of our most popular cases because you can run with a differential,” adds Cascio.

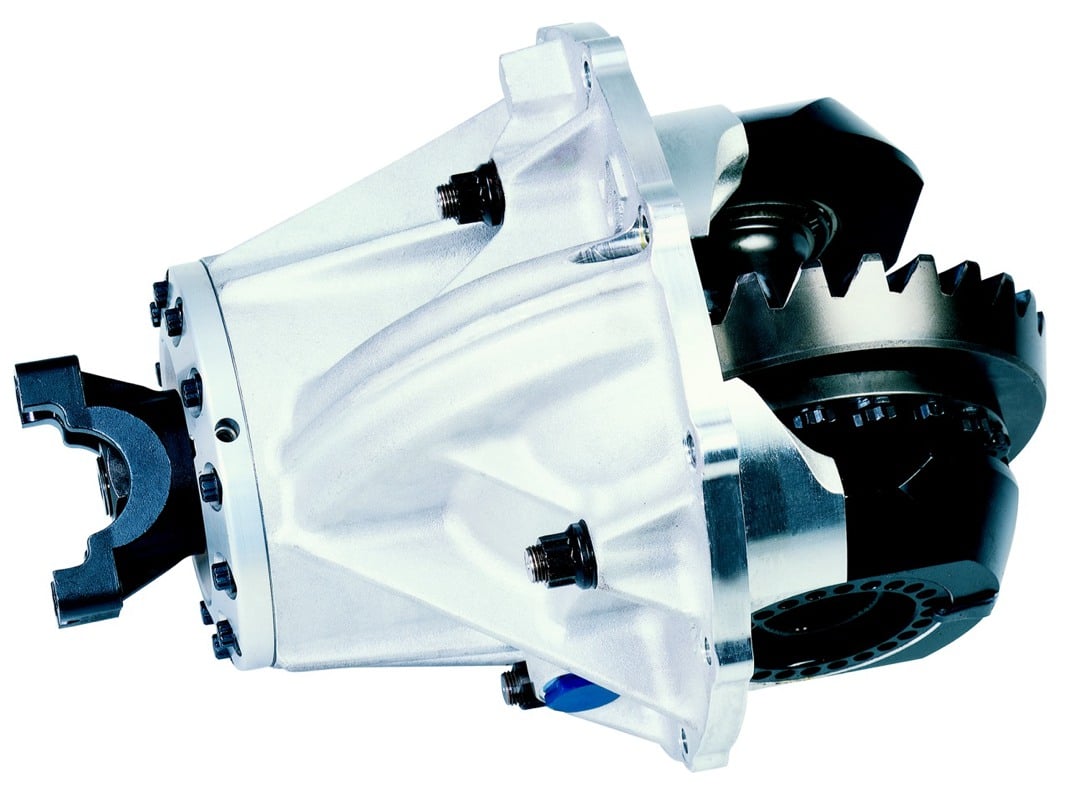

Ultra Aluminum

The strength of this case is evident with the imposing front vertical rib rising from a massive 12-bolt pinion support. They come in three bore sizes: 3.250, 3.812 and 4.00 inch

“There’s a giant channel on the front that actually helps circulate gear oil back into the pinion support,” says Cascio. “Plus, it adds structural integrity to the case.”

The design also sinks the pinion support deeper into the case, making it stronger than a traditional 9-inch, and also uses cap bolts that go through the face of the case.

Two views of the Ultra aluminum case.

“Both the Ultra and the Pro Heavy Duty have provisions for load bolts,” says Cascio. “These are brass-tipped bolts that come in from the side and ride along the back side of the ring gear to help prevent deflection.

The Ultra is for drag racing only, as it will clear only spools and not a differential.

The Ultra is for drag racing only, as it will clear only spools and not a differential.

“All our cases have ball-bearing options,” adds Cascio. “They offer less rolling resistance and definitely a common upgrade for the Ultra case with high-dollar applications.”

Fully assembled Ultra cases can be ordered with a choice of yokes or couplers and spools. The Ultra case also has holes in the pinion support for sensors that pick up signals from optional magnetic collars that can be attached to the pinion. These signals are used for data acquisition, and Strange offers collars with one, two, four or eight magnets, depending on the computer input needed.

The 9-inch center-section assembly is so versatile because it can be accessorized to work with a myriad of combinations. From axle choices to gear ratios to methods of getting power to the pinion, there is a full array of hardware that can work on the street, track or strip. Below is a closer look at these components that are available separately from Strange Engineering and are also available on Strange’s fully assembled center sections, depending on the application.

Gear Sets

The choice is simple: street or strip.

Strange sources gear sets from US Gear, Motive and Richmond in all the popular ratios.

Strange Engineering offers gear sets from three manufacturers in a more durable 8620 material for the street and softer 9310 for drag racers.

“One of the benefits of the 9-inch is that you can put any ratio on any spool,” says Cascio. “There isn’t the 3- or 4-series gears, like on the GM axle. You have adjuster nuts in the case to set the preload and backlash, so there’s no limitation.”

The gear ratio, of course, is dependent upon the application, and so is the choice of materials used to construct the ring and pinion. The standard gears are made from 8620 steel, which is quite durable and suitable for the street, road racing, dirt track and some limited drag racing. The Pro race gears are constructed from 9310 steel and should be used for drag racing only as the metal is softer to help absorb the impact and shock of a hard launch.

“The softer material will wear quicker,” warns Cascio. “You’re going only a quarter mile and then it’s cooling off. If you put a Pro gear into a street application, it’ll build heat and start to wear.”

Again, the versatility of the 9-inch can solve the dilemma of street durability or strip performance by having separate assemblies for each application. High gears and an LSD for comfortable cruising and low gears on a spool for drag racing. For experienced racers, swap time is less than 30 minutes.

Different spool designs are available, including steel and aluminum (far right).

Spools

“Spools are pretty straightforward for a 9-inch,” says Cascio. “It’s basically matching the axle spline.”

Most of the spools offered by Strange are machined from chromoly steel and are available for axles with 28 to 40 spline counts. Some feature additional machining to lighten them. Aluminum spools are also available but only for limited applications. Spools are never recommended for the street, only drag racing, dirt track or off-road racing.

Limited-slip Differentials

Strange offers classic locker and clutch-style differentials from Auburn and Eaton but there’s growing interest in a helical-gear model developed by Strange engineers. Called the S-Trac, this differential works with 35-spline axles and requires a 3.250-inch-bore case.

“It operates as a fully open differential under normal operating conditions,” says Cascio. “When power is applied it wedges all the gears together so the wheels will spin together.”

The helical-gear design allows the gears to engage and disengage smoothly. There are no cones or clutches associated with most LSDs, nor the ratcheting noises of a locker operating. Since there’s so little to wear out, the S-Trac comes with a lifetime warranty.

“It’s very comfortable to run on the street,” adds Cascio. “It’s a good unit to use, whether drag racing, road racing or on the street.”

Other differentials are available for 28- and 31-spline axles, including the Eaton Truetrack, the Auburn Posi and the Eaton Detroit Locker. Strange also makes a clutch-style LSD for 31-spline axles.

Yokes, Couplers

If the vehicle doesn’t have a suspension, such as a dragster or altered, then a solid driveshaft and coupler is the strongest way to drive the pinion gear. Any vehicle with shocks, springs or struts needs a yoke to mate up with the U-joints and driveshaft.

Different styles of yokes and couplers are available on center section assemblies.

Strange offers 28- and 35-spline couplers, including an extra-long heavy-duty model. The yokes are constructed from forged chromoly and heat treated. Lightweight aluminum models are also available for drag racing, as is a 1480 billet chromoly for Pro Mod cars. Street applications have a choice of chromoly or iron. Polishing and chrome plating is also available.

Strange has a variety of options for their 9-inch center sections to meet the needs of almost any enthusiast or racer. It’s little wonder why so many enthusiasts of nearly every brand have adopted the 9-inch Ford as the easy choice for a variety of applications.