Automotive plumbing has been around from the creation of the first automobile. Through all the different efforts to create a vehicle that could take occupants from one place to another, whether the method of creating power was steam or internal combustion, hoses and fittings played a critical role in the design.

Even though hose and fittings are a solution based product that has been around for centuries, there are still a few surprises in the subject. While they may not be the sexiest component to discuss, there are some interesting facts about hoses and fittings that will raise a few eyebrows. We talk about these facts with a little help from the experts at Fragola Performance Systems.

#10 Evolution from Wartime to Automotive

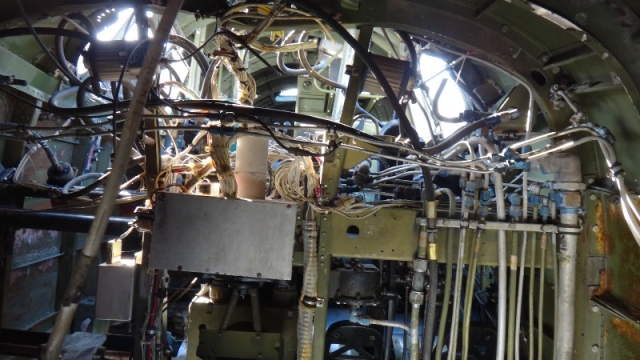

AN Hose and Fittings began as an agreement between forces in the military during WWII. They were used primarily in aviation as evidenced in this WWII era PV-2 tanker’s cargo bay. Photo from Warbird Information Exchange

Chlorinated polyethylene (CPE) hose was developed in response to the Axis powers gaining control of nearly all of the world’s supplies of natural rubber. Prior to the mass development of synthetic rubber, natural rubber was used to manufacture flexible tubing.

A wide variety of synthetic rubbers have been developed since those early days with the synthetic rubber production surpassing natural rubber production in the 1960’s. By the 1990’s, two-thirds of the world’s rubber production consisted of the synthetic variety.

We can thank WWII for the creation of high performance stainless steel-braided CPE hose that was originally designed to be used on aircraft because of the compatibility with aviation fluids.

After the war ended, many of the aircraft mechanics and crew members began using aviation parts in hot rods. Belly tanks became high speed aerodynamic dry lake machines, gunner’s seat became racing seats and steel braided hose and fittings became automotive plumbing on high performance cars.

These stainless steel hoses and the associated AN fittings worked well for decades without a problem, moving fluids from one area to another, then… the fluids changed and the hose material changed to meet the new challenges.

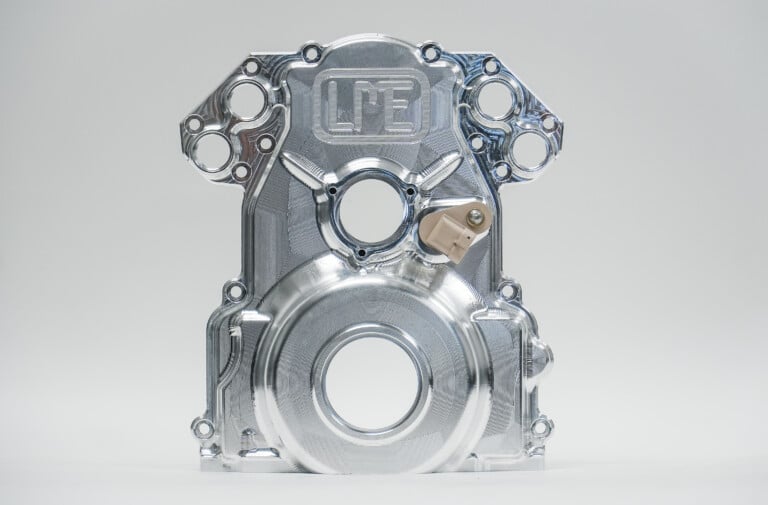

#9 A Style And Size For Everyone

Changing a product based on function or customer request is a big part of the hose and fitting industry. For example, when the Federal government decided to require refiners to blend biofuels with gasoline under the Renewable Fuel Standards, hose and fitting manufacturers had to develop products that could easily handle these harsher fuels for extended periods of time. Different finishes or materials help the fittings become more compatible with the different fluids. Fragola’s 6000 series hose end fittings have lower fuel permeation with some of the more aggressive fluids like modern alcohol fuels.

“Probably the neatest thing about Fragola Performance Systems is our ability to listen to our customers and make changes,” says Fragola’s Jeff Stacy. “We take a lot of pride in the product that we build. Not only is it functioning, but it is also a cosmetically appealing product.”

Fragola's Jeff Stacy credits the flexibility to change as the neatest thing about fittings. From the traditional red and blue finish to the modern black finish and even a chrome style finish, there is a style for everyone.

Beyond performance, Fragola also makes changes to products based on current style. Typically hose ends came in a standard red or blue anodized finish. Fragola was one of the first companies to go outside the norm and offer a full line of fittings in black finish and later in a chrome-like finish.

#8 Considering Weight

When it comes to high performance cars, weight can be an issue. While performance hose and fittings offer solutions for a number of plumbing problems, the more AN fittings that are used in a system, the heavier it becomes.

Using high performance hose and hose ends does not have to be a heavy subject however. “The lightest alternative would be to use our Push-Lok Hose and our 8000 Series Push-Lok hose ends,” said Stacy.

“By using this combination of products it is common to take 20 to 30-pounds out of most vehicle combinations. Our 8000 Series Push-Lok Hose offers good working pressures and vacuum ratings for most automotive racing applications. It can be used to plumb most water, oil, and fuel systems,” he added.

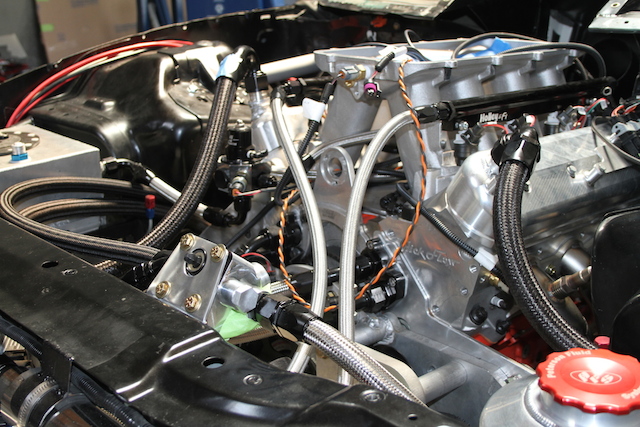

Using AN fittings and hose can help save weight in purpose-built race cars. Photo from www.butyoudontlooksick.com

According to Stacy, the next best step is Fragola’s premium black nylon hose with their Sport-Crimp hose ends. ” You can find these on Pro Mod drag cars, Sprint Cars, Dirt Late Models and Modifieds around the world. If you do not have the availability of a crimping machine, this hose can be used with our 2000 Series, Compression Style, Pro-Flow Hose Ends. This is ideal for the do-it-yourselfer. This product combination will take 15 to 20-pounds out of most applications over a stainless race hose.”

#7 Coatings That Prevent Scratches

When it comes to brake lines, we are talking about the flexible lines that connect the brake calipers and the hard lines on the chassis. Most high performance brake line manufacturers offer a D.O.T. approved and a non-D.O.T. approved stainless steel brake line.

“We offer D.O.T. approved brake lines for on-road use and brake lines for off-road use,” says Stacy. ” What we do that is different is that we also offer a clear coating on our brakes lines to keep them from scratching or marring a frame rail, rearend housing or any part of the chassis.

Stainless steel lines are made of teflon tubing, not rubber, because teflon tubing doesn’t expand under pressure or deteriorate with age. Teflon also resists high temperatures and is compatible with all brake fluids. Because the teflon tubing is fragile, it is protected by a sheath of braided stainless steel.

For the record, there may be brake lines that meet all the D.O.T. specifications, but are considered non-approved because they haven’t been submitted to the D.O.T. for approval. Manufacturers can not legally say that their lines are approved, even if they know that the brake lines meet all the D.O.T. specifications, without actually submitting them to the D.O.T.

#6 Hoses and Fittings For a Variety of Compatibility

AN Fitting to Inch Size Conversion

Dash Size Inch Size Typical Use

-04 ¼” Gauge lines, Vacuum lines

-06 3/8” Fuel return lines

-08 ½” Fuel, Oil, Transmission

-10 5/8” Fuel, Oil, P/S pump

-12 ¾” Fuel, Oil, P/S pump

-16 1” Coolant Lines

-20 1 ¼” Coolant Lines

According to Stacy, Fragola manufactures different lines of hoses that handle a variety of pressure ranges depending on the hose size. Good hose and fittings have published temperatures and pressure limits so that components can be matched to handle the minimum and maximum temperatures and maximum pressures for the systems you are designing. “Under no conditions should anyone use an unrated fitting or hose, or ones that are rated below your system’s capability,” says Stacy. “It’s unsafe. Especially in systems carrying hot oil or pressurized fuel,” he added.

Granted, hose manufacturers usually design their hoses with a safety factor to ensure that a hose will not burst within the published operating range. That safety factor can be as much as 4:1 times the published working pressure. Even with that extra measure of safety, selecting hose that is rated for the pressure and temperature of your system’s normal operation is crucial in building a plumbing system that will handle the job.

A key factor in building your plumbing system is compatibility. “The hose, tubing and fittings should all be compatible with the fluid they will be carrying,” said Stacy. “If your plumbing is designed to move methanol fuel from the fuel cell to the engine, the hose needs to be compatible with that fuel. Otherwise the hose’s inner layer may break down causing leaks or sending particles into your fuel injection or carburetor.” When a hose, fitting O-rings or the fittings themselves breakdown due to incompatibility with the fluid being transferred, high velocity fluid discharge, explosion or burning of the fluid and injuries resulting from inhalation, ingestion or skin exposure can result.

Hose Ratings for Fragola’s Hose Styles:

Premium Black Nylon Race Hose

- Recommended for motorsports applications

- Black synthetic rubber core that is resistant to oil, fuels, coolants and alcohol

- 500 psi working pressure

- Reinforced with a single braid of bright corrosion resistant type 302 stainless steel wire braid

- Operating temperature range of -40 degrees F to +300 degrees F

- Designed to be used with FPS series 2000 hose ends and FPS Sport-Crimp hose ends (not intended for use with 3000 series hose ends)

3000 Series Stainless Race Hose

FPS series 3000 race hose is manufactured to aerospace-quality standards for years of trouble-free service

- 500-1500 psi working pressure

- 2 layers of woven stainless steel, inner layer resists collapse while the outer layer protects against abrasion

- Unique inner liner that is compatible with all hydrocarbon and alcohol based fuels along with all synthetic and natural based lubricants

- Operating temperature range of -40 degrees F to +300 degrees F

- Designed to be used with FPS series 2000 “Pro-Flow” hose ends, 3000 series race hose ends and FPS Sport-Crimp race hose ends

6000 Series P.T.F.E. – Lined Stainless Hose

- P.T.F.E. – lining for corrosive applications like brake fluid. Works well with hot oil and power steering fluid. Handles nitrous oxide with ease.

- P.T.F.E. powder is extruded into a smooth bore product

- Stainless steel braided

- Working pressure based on diameter of hose: -3 through -5 has a working pressure of 3,000 psi -6 has a working pressure of 2,500 psi -8 has a working pressure of 2,000 psi -10 has a working pressure of 1,500 psi.

8000 Series Push-Lok General Purpose Hose

- Manufactured to the same standard as series 3000 race hose but is a perfect alternative when cost or weight savings is a main consideration

- 250 psi maximum working pressure

- Synthetic inner layer covered with fiber braid reinforcement and wrapped with a weather resistant textile cover

- Temperature range to 300 degrees F

- Designed to be used with series 8000 Push-lite hose ends

Series 8600-8700 Parker Push-Lok General Purpose Hose

- The standard for a many applications. Works well when used within the temperature and pressure parameters

- 250 psi maximum working pressure

- Operating temperature range of -40 degrees F to +212 degrees F

- Synthetic rubber tube covered with one layer of textile braid combined with an outer layer of synthetic colored rubber

#5 Don’t Overlook Torque On Fittings

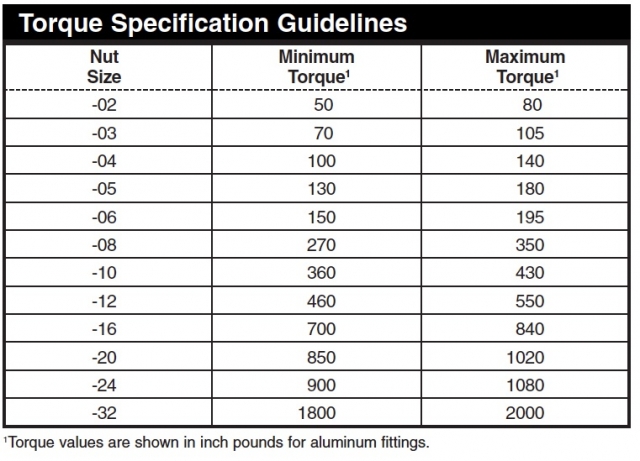

Hose fittings should be treated like other high performance fasteners. They should be installed and tightened to the appropriate torque using a torque wrench. Tightening the hose-end to the fitting can cause a problem if not done correctly. According to Stacy, “Aluminum has a tendency to gall, so we recommend a drop of oil on the fitting’s threads.”

Galling is a form of surface damage arising between sliding solids, distinguished by roughening and creation of protrusions on the surface.

“A drop of oil can help prevent any galling when fittings from different manufacturers are used. Obviously we’d prefer that a builder only use our fittings, but it’s important to keep in mind that threads between different manufacturers can be slightly different. That difference can cause galling or tightening problems,” said Stacy, adding that torquing the fittings will prevent over-tightening and stretching the fitting’s flared surfaces. “Once the flared surface is marred, scratched or stretched, the possibility of a leak is greater.”

Chart from www.vansaircraft.com

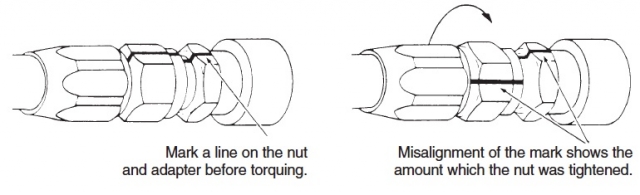

There may be times when the correct torque wrench may not be available. In these cases you can follow one of the alternate tightening methods listed at right. Please note that these methods are for aluminum performance fittings and adapters. Remember, overtightening will result in possible damage to the fitting, resulting in possible leaks.

Drawing from www.vansaircraft.com

Counting Flats Method

- Tighten the nut by hand until it bottoms the seats.

- Using a marker, draw a line lengthwise on the nut and extend it onto the adapter.

- Using a wrench, rotate the nut to tighten. Turn the nut one flat or approximately one quarter of a turn. This applies to all sizes of fittings.

The size of the hose and the fitting matters. Before you spend a lot of money and time making a huge mistake, call the experts.

#4 Size Matters

“Maximum recommended operating pressure goes down as the tube or hose size goes up,” says Stacy. In general, pressurized fluid inside the hose assembly varies with pressure and flow rate. The size of the components must be adequate to keep pressure drops to a minimum or to prevent the hose from aging due to heat generated by a higher fluid velocity. In the case of fluid flow, speed equals heat. Lines intended for pressure lines, return lines and suction lines all have different fluid velocity recommendations.

Parker Hose uses the acronym STAMP to help select the proper hose for each application. STAMP refers to Size, Temperature, Application, Media and Pressure. Obviously, size is important because it is represented as the first letter in Parker’s acronym. The hose I.D. must be sized accurately to obtain the proper flow velocity. A flow that’s too slow results in sluggish system performance, while a flow that’s too high causes excessive pressure drops, system damage, and leaks.

The rest of Parker’s acronym are equally important for consideration. When it comes to temperature, fluid temperatures can have a much greater impact on hose life. For example, rubber loses flexibility if operated at high temperatures for extended periods.

Application refers to how the hose assembly will be used. For example, applications where hoses will encounter rubbing or abrasive surfaces would best be handled by our family of abrasion-resistant hoses with both tough and super tough covers. When application space is tight, bend radius is another important consideration.

The media part of the STAMP acronym reminds the designer to order a hose that is compatible with the medium being conveyed. Compatibility must cover not just the inner tube, but the cover, hose fittings, and O-rings as well.

Finally, when considering hose pressure, it’s important to know both the system working pressure. Hose selection must be made so that the published maximum working pressure of the hose is equal to or greater than the maximum system pressure. Knowing the pressure output of the water pump, fuel pump or power steering pump is a necessity when it comes to hose selection. It’s not enough to plan for the normal operating pressure, spikes and surges in the system must be considered as well.

According to Stacy, the first thing that you need to keep in mind when designing your system is, “Before you make a mistake, call us.”

#3 A System With Less Fittings is Lighter and Safer

“The latest trend is building cars lighter. To be competitive or gain a little competitive edge, build your systems as light as safely possible. Going to the hardware store for fittings is going to result in bulky and heavy fittings. Buying our specialized racing fittings and hose-ends will result in a stronger and lighter system,” claims Stacy. In addition to saving some unnecessary weight, designing a system with fewer fittings has another benefit. “Fewer connections means fewer potential leak points,” Stacy added.

Taking advantage of the wide variety in fittings available will help. Stacy used this example, “Let’s say you need to route a hose or tube 180 degrees. You can use two 90 degree fittings and it will do the job but choosing a 180 degree fitting will accomplish the same thing with less weight, and more importantly, fewer potential leak points.”

Part of choosing the best fitting is knowing what is available.

AN fittings are based on an agreement between the Army and Navy. Photo from www.dvids.net

#2 AN Fittings Are Based On A Military Agreement

AN fittings are derived from the military specifications dating back to World War II for use on aircraft. Developed by the Air Force, which was a part of the Army at that time, was primarily used on hydraulic lines in aircraft. Because the Army Air Corps and the Navy were the only two services with aviation branches, they joined into an agreed specification on the fittings which led to the term AN spec, meaning Army and Navy specification. There have been documents in the past that referred to the AN name having derived from Air Force and Navy. Either way, the specifications of the fittings came from a joint agreement between the services.

AN fittings are a flare fitting, using 37° flared tubing to form a metal-metal seal. They are similar to other 37° flared fittings, such as JIC fittings, which is their industrial variant. The two are interchangeable in theory, though this is typically not recommended due to the exacting specifications and demands of the aerospace industry. The differences between them relate to thread class (how tight a fit the threads are) and the metals used.

#1 Home Testing

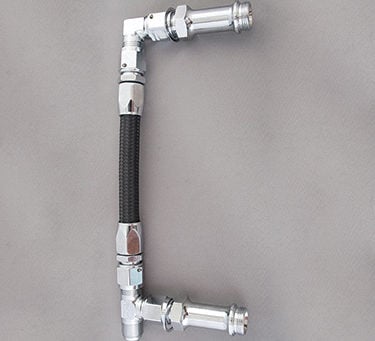

Flushing and testing AN hose assemblies can be tested and checked at home. Once reserved only for major hose making shops, the ability to flush a hose assembly and check for leaks is now accessible to the do-it-yourselfers. “We were looking for a way for the DIY guy at home to be able to easily flush out his hoses after assembling a new system,” says Stacy. Fragola’s Master AN Pressure Test and Flush Out Kit (Part # 900557-BL) is compatible with AN hoses from -04 all the way up to -16 AN sizes. After making numerous cuts, and assembling new braided hoses, the completed system needs to be flushed to remove debris.

Fragola’s Master Flush Out and Test Kit allows for flushing and testing of the lines and components.

This kit allows the user to attach a garden hose to a line and flush the entire system with tap water prior to ever pushing fluid through it. It also can be capped to allow the user to perform a leak check using tap water, rather than risking a check with fluids like gasoline. The kit includes adapters to use it on the specified hoses sizes, and it can be used to flush any Fragola hose. As an added bonus, the kit can be used to quickly flush out lines and components after engine or transmission failure.

That’s Not All

There is a lot more to AN hoses and fittings than most of us will ever know. Information about hoses and fittings is readily available with any search beginning with Fragola Performance Systems homepage. Repetitive use of the AN hose and fittings proves the true value of these components as they stand up to the test of time. The final word rests in economy and true value. Because the fittings are so durable, and when properly maintained, they seemingly last forever, the intrinsic value of the fittings is beyond anything that a simple rubber hose and band clamp can provide.