Chemical intercooling has become increasingly popular as a method of reducing the intake air temperature and adding octane on forced induction vehicles. This form of intercooling is done with the use of a mixture of water and methanol that is injected into the vehicle’s intake air stream. AEM Electronics has recently updated their popular water/methanol system and controller adding more features to the unit. With the horsepower of our Project Wild E Coyote ever climbing, we decided to install and test this controller and see just what kind of a difference it could make in our intake air temperatures.

Chemical intercooling has become increasingly popular as a method of reducing the intake air temperature and adding octane on forced induction vehicles. This form of intercooling is done with the use of a mixture of water and methanol that is injected into the vehicle’s intake air stream. AEM Electronics has recently updated their popular water/methanol system and controller adding more features to the unit. With the horsepower of our Project Wild E Coyote ever climbing, we decided to install and test this controller and see just what kind of a difference it could make in our intake air temperatures.

Why Chemical Intercooling

A byproduct of forced induction and the compressing of air is the heat that is generated during this process. Management of this heat can be done in a variety of ways, the most common way being to intercool the boost. Intercooling is typically done by an air-to-air or air-to-water system. Since traditional intercoolers rely on surface area to cool the compressed air charge, they are limited by the size that can fit within a specific application. These types of intercoolers work well, but can also create packaging issues since their efficiency is based around their design and size, and they typically won’t be able to compensate for additional temperatures created by increased boost pressure.

A byproduct of forced induction and the compressing of air is the heat that is generated during this process. Management of this heat can be done in a variety of ways, the most common way being to intercool the boost. Intercooling is typically done by an air-to-air or air-to-water system. Since traditional intercoolers rely on surface area to cool the compressed air charge, they are limited by the size that can fit within a specific application. These types of intercoolers work well, but can also create packaging issues since their efficiency is based around their design and size, and they typically won’t be able to compensate for additional temperatures created by increased boost pressure.

Water/methanol injection systems typically weigh less than upgraded or larger intercoolers. Conversely water/methanol injection systems need only enough room to mount a small reservoir and controller.

For Wild E Coyote, we installed AEM’s V2 One Gallon Water/Methanol injection system, part number 30-3300. AEM has developed a new controller for this system, making it easier than ever to fine-tune your injection percentage. This system is MAP based, meaning it looks for a vacuum or boost signal as a reference for when to inject the mixture. This reduces installation complexity and makes tuning the system very straight-forward.

Linear Progression

You basically set the boost pressure that kicks the system on, and then the boost pressure for maximum flow. The internal MAP sensor allows any turbocharged or supercharged engine to work with this syste. -Paul St Clair, AEM

St Clair mentions the setup is very easy, “You basically set the boost pressure that kicks the system on and then the boost pressure for maximum flow. The internal MAP sensor allows any turbocharged or supercharged engine to work with this system.”

The V2 system uses a conductive style fluid level sensor (right) to detect fluid level. This sensor is less prone to shut the system off due to slosh versus the older style float sensor that was previously used.

AEM has incorporated two dials on the face of the controller one for the minimum boost pressure that the system activates at and one for the maximum. The maximum should be the maximum boost that the engine sees. Using these settings the controller will progress the amount of water/methanol being injected in a linear fashion so that at the maximum setting the system is injecting the maximum amount of water/methanol that the installed jet will flow.

Pump

While the controller is the brains of AEM’s water/methanol system the heavy-duty pump is the heart of it. This pump is actually overkill for the system, capable of providing a far greater amount of fluid flow than what is needed.

The way the system is set up, the pump is internally bypassed. The system runs the pump as a constant on, this means that when there is no demand from the controller for water/methanol injection the pump’s output is reduced and it continually recirculates. Once the demand is signaled, the pump increases its output to safely inject the appropriate amount of water/methanol. Keeping the pump on all the time reduces the delay time in activation of the system. Additionally there is a check-valve located within the injection nozzle that is set to 16 psi. This ensures that no water/methanol is injected until the appropriate pressure is achieved. St Clair says this ensures a fine injection spray, and that the system does not dribble.

The pump must be mounted in-line with or lower than the fluid reservoir. On our 2011 Mustang, we reused the windshield washer reservoir as our container for the water/methanol mixture. All we needed to do was install the push-lock fitting into the bottom of the reservoir.

If an owner decides that they don’t want the pump to run constantly, AEM has an optional solenoid kit that can be purchased separately to turn the pump off.

Safe Trigger

Two vs One

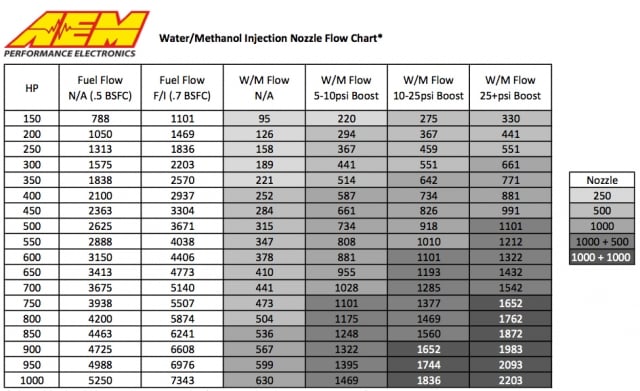

Since Wild E Coyote is headed to making around 1,000 hp at the crank, we were going to exceed the recommended power levels that a single nozzle can handle. As such, we ordered a second nozzle from AEM, part number 30-3312, and installed it side by side with the first nozzle – a 1,000cc and a 500cc. This kit includes a T-fitting, as well as additional hose and jets so it can be sized accordingly. The pump in the system will easily support running two nozzles with no additional modifications.

The second way Boost Safe works is by triggering a failsafe automatically. The green wire that is connected to the controller is a 1.7 amp ground. This can be used to trigger a solenoid connected to a wastegate or blow-off valve. It could also be used to trigger an onboard electronic device such as an ignition box to pull timing out, or even a stand-alone aftermarket fuel injection to switch to a safer tune that doesn’t incorporate water/methanol injection.

Swappable Jets

The AEM water/methanol controller also includes three different size jets for the included nozzle. Those jet sizes are 250cc, 500cc, and 1,000cc per minute. This allows the water/methanol mixture to be custom tailored to the specific application. Additionally the nozzle can be disassembled easily to make changes should owners decide to up their horsepower. The washers for the nozzles are reusable or replaceable making the system easily serviced.

Install

Installation requires only making a few connections external of the water/methanol system, primarily for power, and the remote mounted LED light. The controller is not waterproof and needs to be installed in a safe place within the car, where it can be accessed for making adjustments, or testing the system.

When mounting the nozzle, it needs to be placed in the appropriate position “We want the nozzle after the mass airflow sensor and before the throttle body, about halfway if at all possible,” says St Clair.

The pump is gravity fed by the fluid reservoir so it needs to be mounted appropriately. This means the pump should be mounted at the same level as the fluid outlet on the reservoir, or lower than that outlet if at all possible. This will ensure that the pump can be constantly fed water/methanol for injection.

Above is the first version on the AEM Water/Methanol controller with the V2 pictured below it.

Tuning

Some enthusiasts will use a water/methanol system on their street car or daily driver, while others may only use it on race day. According to St Clair, this system can be used for track or race days to allow for more aggressive tunes without having to run race fuel. “Many users will run these systems as octane on demand, allowing them to run more boost or timing without the need to switch from pump gas.”

St Clair says since the methanol component of the mix is a hydrocarbon, introducing it into the system does require tuning. Air/fuel ratios will need to be adjusted appropriately to compensate for the additional fuel that’s being added, meaning tuners will have to determine the appropriate amount of fuel to obtain the desired AFR.

The V2 controller makes fine tuning the AEM water/methanol system as easy as turning two dials. We installed ours under the driver’s seat for easy access for tuning and to keep it away from dust, moisture, and heat.

Additionally, the effect of the water expanding into steam creates pressure within the cylinders, and according to St Clair this increases combustion pressure, similar to raising the compression ratio. Thus tuners will again need to compensate appropriately.

Newer Mustangs like our Coyote powered 2011, can compensate for a small amount of water/methanol injection since they’re equipped from the factory with wideband oxygen sensors. Since wideband systems are capable of reading and compensating for a greater variance in air/fuel ratio, we can run a small amount of water/methanol without the need to change our tune. We had Ryne Cunningham at Cunningham Motorsports handle the tune after our install. “One of the advantages the Coyote engine has, is that since it uses wideband sensors, if the water/meth injection fails, the computer will pick it up and try to compensate for it,” says Cunningham.

Capturing Temperature

To log and trap our temperature drop, we installed a GT500 intake air temperature sensor into the air inlet tube of Wild E Coyote.

The Coyote’s mass air flow sensor also houses the intake air temperature sensor. Since we can’t spray our water/methanol mixture through the MAF, we had to find a way to monitor and record our changes. To do this we turned to the Ford parts bin and were able to come up with a GT500 intake air temperature sensor. A bung was welded into our intake pipe just past where the water/methanol nozzles are installed. We then tapped into our harness at the MAF and rerouted the wires for IAT to the GT500 sensor. We can now use our diagnostic port to datalog the intake air temperature PID and see in real-time the changes in temperature when we begin spraying the water/methanol mixture. “If you move the intake temperature sensor like this you can then watch the intake air temperature drop as soon as the water/methanol starts spraying,” says Cunningham. “Typically we advise customers to start using a water/methanol system when we see intake air temps over 140 degrees. With the water/methanol injection we can see a drop in temperature by as much as 40-50 degrees Fahrenheit.”

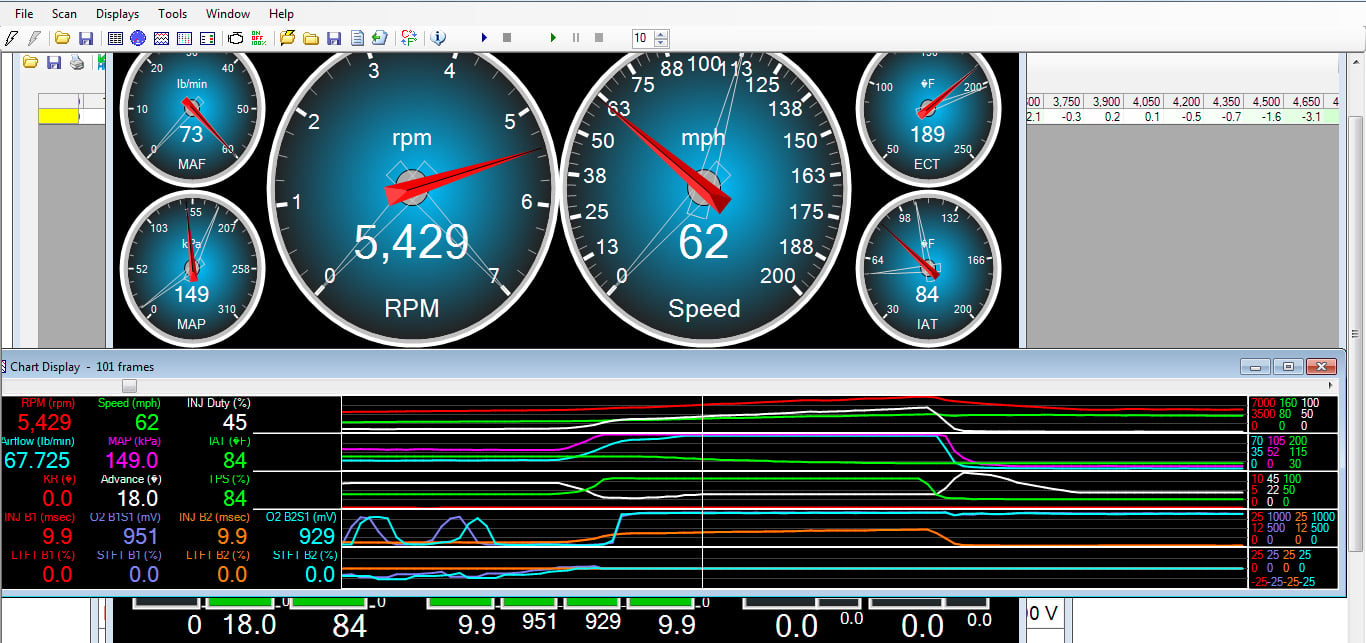

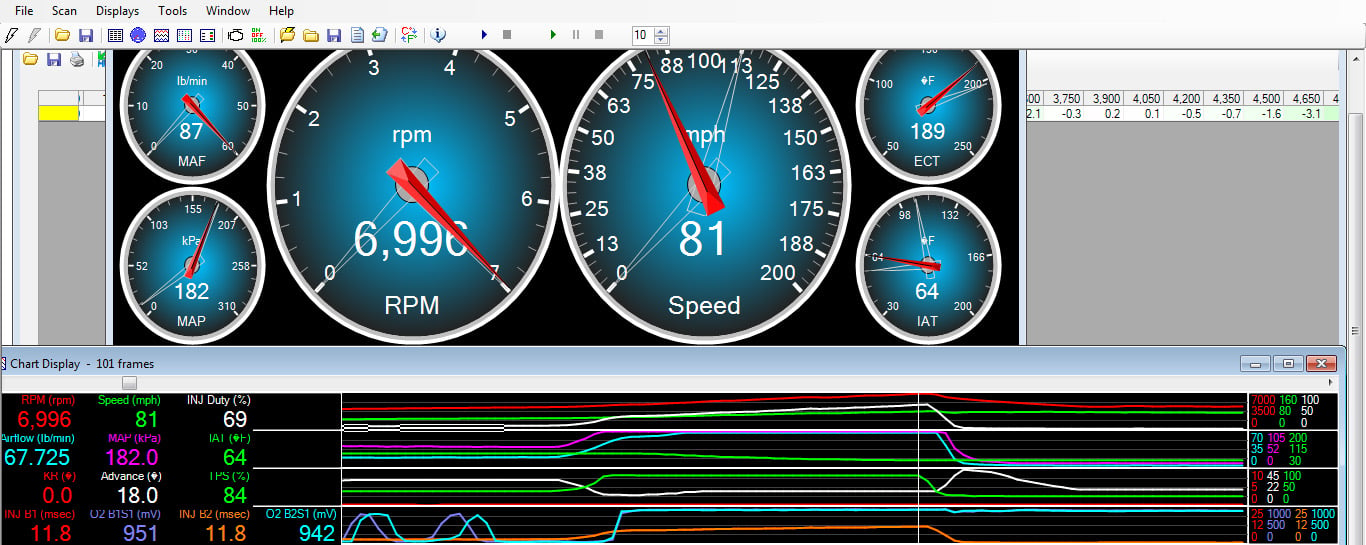

These three screen shots are examples that indicate the intake air temperature drop once the water/meth mixture is introduced. Notice that even with a small amount of water/methanol mixture being injected there's a drop of 33 degrees in intake air temperature.

Cunningham also says it is critical to follow the guidelines for setup of any water methanol system as set by the system’s manufacturer, as well as their guidelines for tuning the system. He also says wiring the system properly is critical. “Making sure that everything is wired exactly as it should be is really important because you don’t want the system to suddenly fail.”

Breaking down three screen shots that Cunningham sent us from a dyno run, we can clearly see what is going on with the engine. Typically with a rise in RPM and boost pressure intake air temperatures would increase. Looking at these three screen shots where water/methanol injection takes place we can see that the opposite is true. Notice the first shot starts the IAT at 97 degrees, by the third shot, the IAT has dropped to 64 degrees.

Also check out the timing advance. Notice here that timing continues to advance from 13.5 degrees in the first screen shot all the way to 18 degrees in the last photo. Since the water/methanol mixture cools the incoming air charge and introduces additional fuel octane, tuners like Cunningham can get more aggressive with timing when the water/methanol mixture is introduced, this in turn allows for more horsepower.

With our AEM Water/Methanol system now in place, we’re one step closer to faster times at the drag strip in Wild E Coyote thanks to a more aggressive track tune.