Auto-racing is a perilous sport, we are reminded time and time again how fragile the human body can be when dealing with the energy and inertia of a car. Many safety advancements have been made in the last century, but few have developed and changed more than the helmet. The most important component of a personal safety equipment collection; the helmet, is a totem many drivers hold overhead in victory at the end of a hard fought exhibition of speed, skill, and calculated risk. These cocoon-like shells become an extension of your most vital appendage, providing increased protection.

Auto-racing is a perilous sport, we are reminded time and time again how fragile the human body can be when dealing with the energy and inertia of a car. Many safety advancements have been made in the last century, but few have developed and changed more than the helmet. The most important component of a personal safety equipment collection; the helmet, is a totem many drivers hold overhead in victory at the end of a hard fought exhibition of speed, skill, and calculated risk. These cocoon-like shells become an extension of your most vital appendage, providing increased protection.

No longer a simple leather skull cap used at the turn of the century, helmets have progressed through research using a variety of designs and materials, and are an innovative extension that have evolved to protect users. Selecting a helmet is arguably the most important decision you will make. If there is one thing to take away, it’s that while the budget racer may cut corners and pinch pennies, safety equipment is never the place for cost cutting! Buying the best safety gear possible is a mandatory duty to yourself, your family, friends, event organizers, and emergency crews or first responders.

Helmet Design And Construction

The obvious purpose of a helmet is to protect your head, your brain specifically. Injuries to the head can be sustained easily from different directions and occurrences. When we spoke with Kelli Willmore of Impact Racing, she shed some light on the specifics of helmet design and construction, along with important considerations when selecting a helmet.

The obvious purpose of a helmet is to protect your head, your brain specifically. Injuries to the head can be sustained easily from different directions and occurrences. When we spoke with Kelli Willmore of Impact Racing, she shed some light on the specifics of helmet design and construction, along with important considerations when selecting a helmet.

“The single most important aspect of purchasing a helmet is confidence in the the brand and manufacturer. Well-known and longtime name brand safety companies are going to have a proven track record, and the systems and processes in place, to ensure that the same helmet lay-up that was tested, and passed the required Snell Foundation standards, is also the same helmet that is being produced and shipped to the consumer.” said Willmore.

The single most important aspect of purchasing a helmet is confidence in the the brand and manufacturer. -Kelli Willmore, Impact Racing

Multi-density foam padding can help mitigate both high-velocity and low-velocity impacts.

In the case of a fire, most racing helmets are rated manufactured using Nomex for the interior fabric. In addition, shields are rated to withstand heat. Direct exposure to flames is not the only problem, however. Internal respiratory damage is a primary cause of injury to lungs. A well-fitting helmet equipped with a skirt, can help prevent such injuries.

How Helmet Weight Factors In

Considered in the construction of helmets weight of a helmet is not just a comfort selling point, but also a safety feature. A light-weight helmet has less inertia, and therefore carries less energy at a given speed. If you can reduce the mass of the helmet, the total energy imparted on your head will be less. Helmets in the three-pound range are the leaders in this technology, and offer the same safety certifications, and increased comfort to heavier options. According to Willmore, “No helmet can completely protect the against a concussion as it is impossible to keep the brain from enduring excessive movement inside the skull when traumatic forces have been exerted on the body therefore it is important to keep the weight of the helmet minimal to reduce the loading forces.”

A surprising cause of head injuries is not impact but G loads. Willmore recounted a study she read concerning this specific problem; “Stephen E. Olvey M.D., associate professor of Clinical Neurology and Neurosurgery at the University of Miami Health System and Founding Fellow at the FIA institute for Motorsport Safety and Sustainability, reported that nearly 50 percent of racing related concussions do not involve a direct impact. In a recent seminar at the International Council of Motorsports Sciences, Olvey reported that approximately half of the concussions are from acceleration/deceleration inertial loading forces (‘whiplash’) rather than a direct impact to the head.”

How Are Helmets Made?

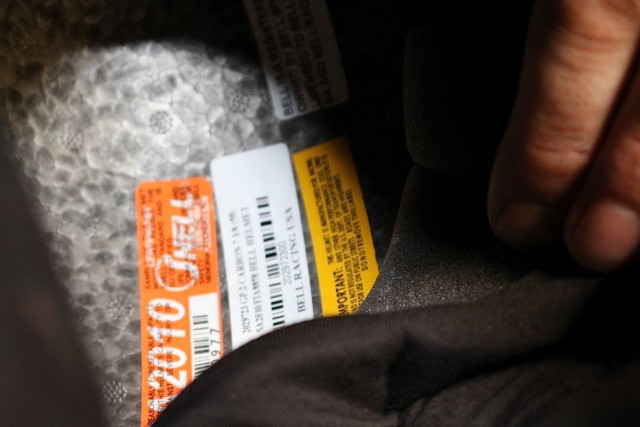

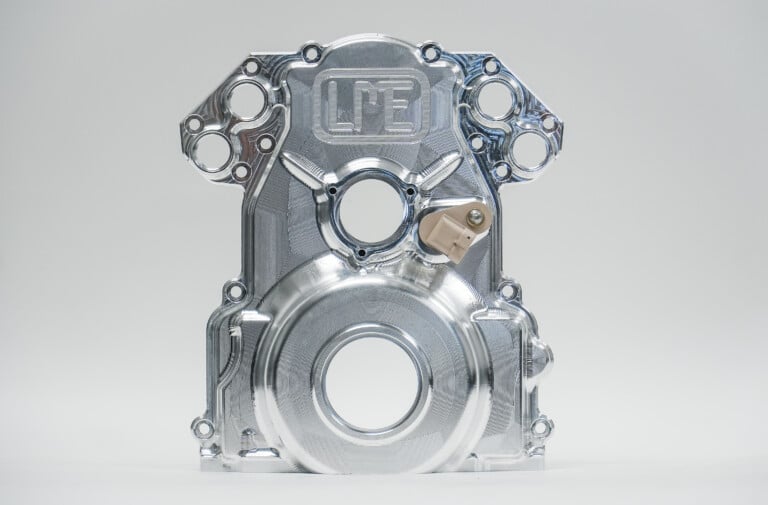

Modern auto racing helmets are manufactured using nearly all composites, fiberglass, carbon fiber and the like. Manufacturing with this high tech material involves intricate tooling and processes. According to Kyle Kietzman of Bell Helmets, “advanced compression molding techniques” are used to manufacture their shells.

The tooling, molds, and secondary shell processing for compression molding. Photos courtesy of Bell Helmets

“The approaches to design for attenuating low-velocity versus high-velocity impacts will require most entry-level helmets to either be constructed from heavier or more expensive materials in order to achieve the required performance,” reflected Willmore.

She went on to explain, “Mitigating a broad range of impacts is a balancing act as it often requires the use of variable density inner liners as well as additional millimeters of material added to the outer shell. The challenge is offering an [affordable] helmet that can control both high and low-velocity impacts without adding weight.”

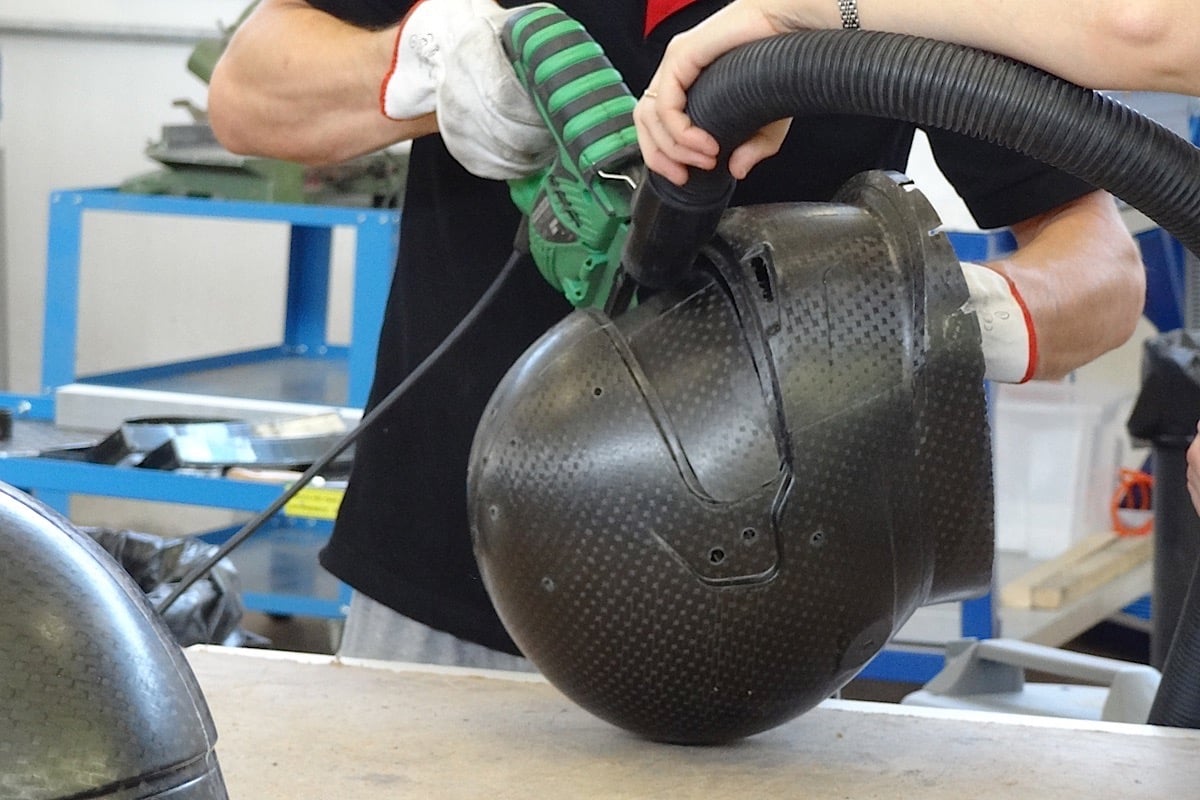

Left: A Bell helmet is cut while a vacuum collects the dust. Right: An Impact helmet is drilled with the aide of a jig.

Come Out Of Your Shell

Helmets range in price points from as little as $20 to in to the five-figure range, depending on quality, materials, and features. The biggest difference between the range of helmets is the raw materials from which they are made. Starting at the bottom of the line, there are helmets featuring a blow-molded ABS or polycarbonate plastic shell, and a hard foam interior. These helmets may be certified as safe, but make compromises in quality for economy. Plastic shells crack upon impact, and once the outer shell cracks and exposes the foam interior it is rendered useless for future wear. These helmets often have cheaply formed foam padding that may not be comfortable, or replaceable.

A custom paint job can really set one helmet shell apart from the rest!

The next level of helmet safety adds more technological features. A fiberglass shell helmet utilizes a fiber-reinforced polymer shell to better absorb and dissipate impacts and penetration. When a composite shell takes an impact it has a tendency to crush, rather than shatter. This crumple zone effect helps slow deceleration of the wearers head, decreases the G loads, and may withstand another strike in the same crash.

At the top range are helmets constructed out of exotic composite materials such as carbon fiber, and Kevlar. These materials offer the most superior mechanical properties, resisting plastic deformation (deformation that takes a set) better than lower range helmets. Generally starting at over $1,000, they are well worth the added protection, and features and could save your life.

At the top range are helmets constructed out of exotic composite materials such as carbon fiber, and Kevlar. These materials offer the most superior mechanical properties, resisting plastic deformation (deformation that takes a set) better than lower range helmets. Generally starting at over $1,000, they are well worth the added protection, and features and could save your life.

Internal Design And Features

Helmet design extends well below the surface structure. The selection and construction of padding and visors contribute to the overall fitment and visibility. Bell Helmets employs the use of multi-piece, multi-density foam liners. According to Kietzman, these liners allow engineers to optimize the comfort of the helmet, while mitigating both high and low velocity impacts.

Fitment is extremely important when selecting a helmet. More often than not buyers end up with a helmet too big for them. “Pay attention to the published sizing chart because that varies from manufacturer to manufacturer.” Kietzman said.

Pay attention to the published sizing chart because that varies from manufacturer to manufacturer. -Kyle Kietzman, Bell Helmets

Visor opening size can vary from helmet to helmet, manufacturer to manufacturer, and may be subject to regulation by certification. If you wear glasses under your helmet, or feel claustrophobic, you may want to try multiple visor sizes to find the most comfortable field of view.

Visor opening size can vary from helmet to helmet, manufacturer to manufacturer, and may be subject to regulation by certification. If you wear glasses under your helmet, or feel claustrophobic, you may want to try multiple visor sizes to find the most comfortable field of view.

Santctioned Testing Requirements (Homologation)

“Another factor to consider frankly is the requirement of the sanctioning organization.” reminded Kietzman. When choosing a helmet make sure the organization in which you plan to race allows the type you are choosing. The FIA (Federacion Internacionale de l’Automobile) is a worldwide sanctioning body for most motorsports. The FIA specifies safety requirements and stipulations the same way any domestic organization does, including SCCA, NHRA, NASA, SCORE, etc.

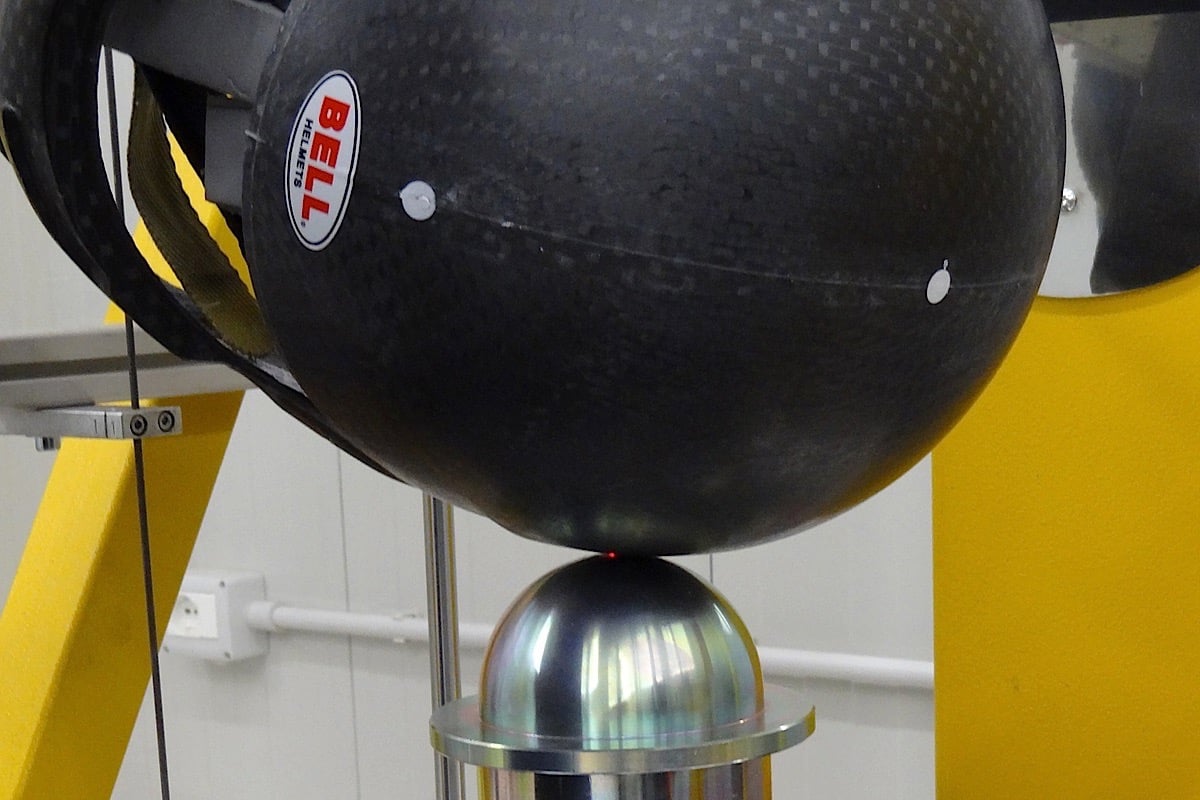

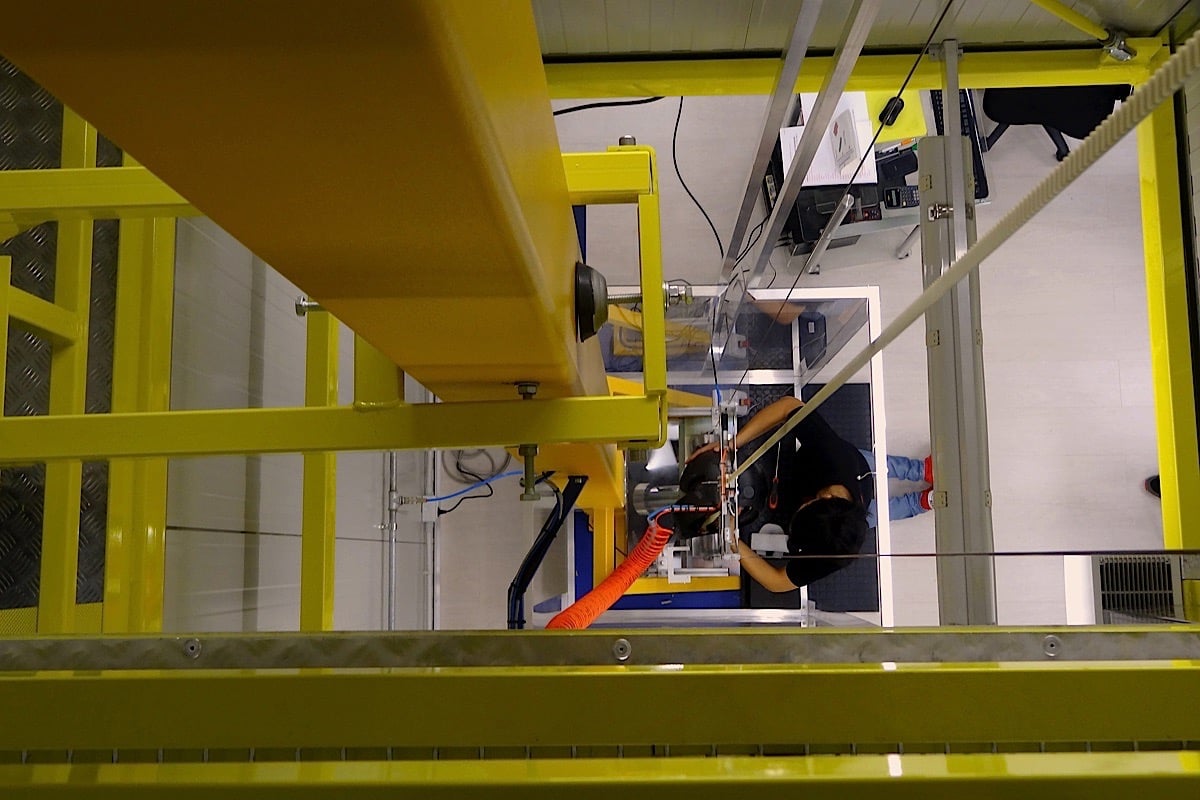

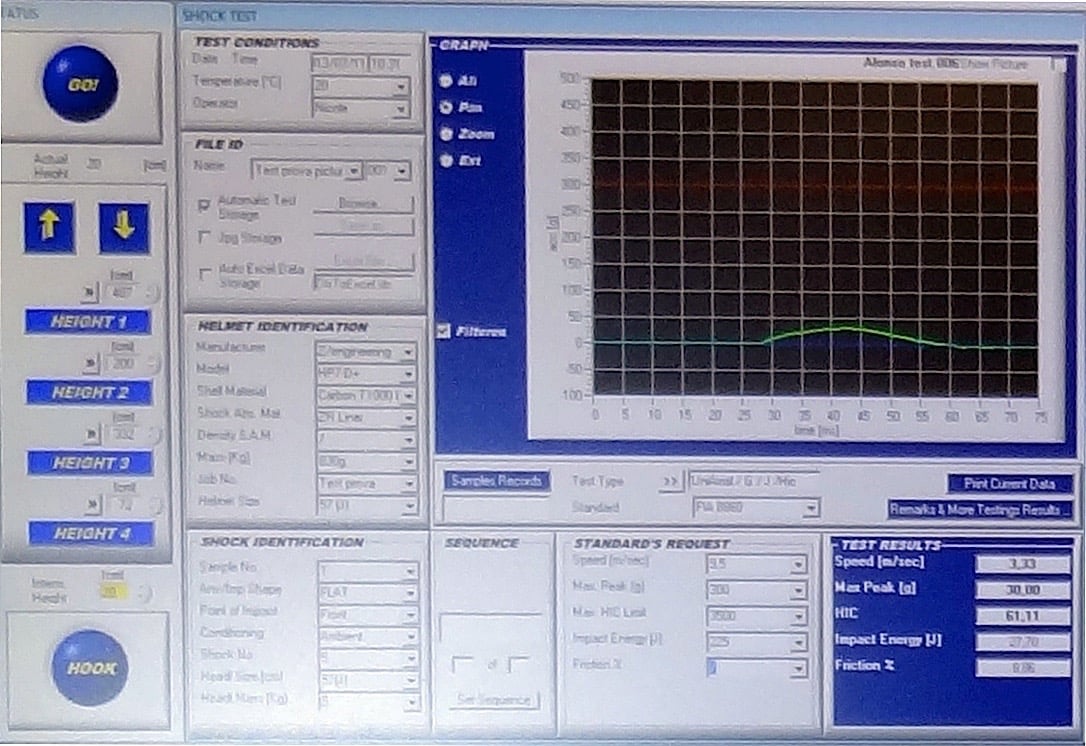

Many manufacturers conduct in-house sample testing. Photos courtesy of Bell Helmets

The FIA does not conduct their own destructive testing, instead they contract with approved quality control test labs that specialize in test-engineering products. The most widely recognized organizations are SFI and Snell. Both Snell and SFI have pioneered testing procedures strictly regimented in their standard operation procedures. The obvious crush and penetration tests are conducted by both, but each has their own specific specialty tests to keep pace with the latest technology and life-saving techniques.

Testing And Compliance

The FIA states specific testing criteria must be met before a helmet can be approved. FIA Standard 8860-2004, states that helmet testing will be conducted by third party labs and adhere to provided forces, conditions, and test planes. Third party testers go above and beyond the requirements demanded by the FIA. Testing specific capacities such as flame resistance, chemical exposure, and removability are not required; Attention to detail and pride of certification both Snell, SFI and manufacturers have for their helmets, is up to them. The general breakdown is as follows:

FIA Demands

FIA testing and homologation requirements can be found here.

- Linear Impact: Helmet and head form subjected to 225 Joules (a unit of energy measurement), in the form of 5kg at 9.5 m/s

- Projections and Surface Friction: Oblique strikes against an anvil must not exceed 25ns and 12.5ns in different tests.

- Penetration Test: 4 Kg impacter dropped from 3 meters and 12 cm

- Crush Tests: Longitudinal and lateral

- HANS Device Anchor Tests: Anchors subjected to 3.5kN for 5 seconds

Snell:

Snell Memorial Foundation testing procedures can be found here.

- Peripheral Vision: The opening port area is inspected for adequate visibility.

- Extent of Protection: Helmet coverage of anatomical vulnerabilities is mapped.

- Conditioning: Hot, cold, wet

- Positional Stability (Roll Off): The helmets ability to stay on the wearer’s head when a pulling force is a applied.

- Dynamic Test of Retention System: The chin strap is subjected to cyclical loads to ensure it does not come un-done.

- Impact Management Tests: Low-velocity, lateral.

- Chin Bar: A deflection test involving a dropped weight.

- Shell Penetration Test: A 3 Kg pointed weight is dropped on the shell.

- Face Shield Penetration Test: Visor is shot with an air rifle.

- Flame Resistance: Helmet subjected to 790-degree Centigrade flame with interior temperature monitoring.

- Removability: Ease of removal with a potential neck injury.

SFI

SFI Foundation certification procedures can be found here.

- Chemical Exposure: A solvent mixture is applied to the helmet for at least 10 second.

- Environmental Exposure: Ambient temperature, low temperature, high temperature, water submersion

- Fastening Mechanism (visor): Inadvertent visor lifting is tested.

- Penetration (visor): A steel projectile is dropped on the visor.

- Retention System: A jaw movement simulator us used to test the chin strap holding.

- Chin Bar: A flat impact surface is used, and a maximum of 30 G is allowable deceleration.

- Impact Attenuation: Flat, hemispherical, vertical, and bar anvils are used to test attenuation.

- Penetration (Shell): A 3Kg striker with a tip hardness of 60 Rockwell is dropped from 3 meters.

Special Features

Eject Helmet Removal System

Helmet removal after a crash has always been a delicate procedure for safety and medical personnel. The threat of exacerbating a neck injury with pulling force is a valid concern when dealing with an unconscious patient.

Products like the Eject Helmet Removal System use an inflatable bag to push the helmet off the wearer, reducing the need to pull the helmet off the wearer’s head.

Fresh air ventilation systems keep helmet visors from fogging on the inside, and provide clean circulating air for dusty environments. Endurance racing applications demand hydration provisions to keep drivers full of fluids in the hot environment of a race car.

Fresh air can be supplied via scoops or a forced air tube attached to a fan and air filter.

Electric water pumps, and bite valve style hoses can be installed to supply water to the driver at the press of a button. Drag racers in the alcohol and nitromethane community need protection from the overwhelming fumes created inside the cockpit from burning these volatile fuels. Helmets made for these drivers feature filtration systems built into the helmet like a gas mask.

A chain is only as strong as it’s weakest link, and with helmet technology today the latest exploration is in head and neck restraint systems (HNRs). Devices like the HANS, Safety Solutions R3, and Deccel harness are examples of devices that attach to helmets and the torso to help prevent neck injuries resulting from whiplash and hyperextension. Most helmets come pre-drilled with provisions for the mounting hardware. An increasing number of organizations now make them a mandatory piece of safety equipment. In October of this year, the next incarnation of helmet certification will take effect; Snell 2015. “All SA2015 homologated helmets will have M6 terminal hardware adapters,” according to Kietzman.

All SA2015 homologated helmets will have M6 terminal hardware adapters. -Kyle Kietzman, Bell Helmets

After the tragic accident involving Formula 1 driver Ayrton Senna, the FIA began to research helmet design and capabilities. The FIA 8860 certification was proposed to see the feasibility of manufacturers producing helmets with nearly double the protection. Using exotic aerospace composites and design; “Bell was the first manufacturer to certify in that ‘super helmet’ standard,” reported Kyle. He went on to explain that these super helmets command an extra price due to the construction, but “absorb up to 40 percent more energy than standard models.”

The next Snell homologation date was October 1, 2015. After this date, helmets will be available with the latest design and certification. According to Willmore, “Helmets homologated to SA2015 offer dramatically improved performance standards for impact management and are required to meet stringent energy attenuation benchmarks.”

The HANS device is one of many head and neck restraint options, but mandated by several organizations.

Beyond the certification of helmets both NASCAR and IndyCar have started testing the drivers themselves. “A mandated pre-season neurocognitive baseline testing [has been implemented] as part of their comprehensive concussion prevention and management program for all their drivers,” reported Willmore. “After a suspected concussion or head injury has been sustained, a driver is then re-evaluated after the injury and the results compared. By conducting a thorough evaluation prior to the start of the racing season, doctors have a baseline to compare post-injury results to and make informed decisions on when it is safe for a driver to return to competition.” further explained Willmore.

When choosing a helmet, make sure you trust your brand. Look for the features necessary to your activity or motorsport. Make sure your sanctioning body has approved the helmet before buying. And, most of all, consider how much you value your head — the helmet you choose today could save your life on the track tomorrow.